Dyeing Machinery

Showing all 12 results

-

Dyeing Machinery

Atmospheric Soft Over Flow

Atmospheric Soft flow

The Atmospheric Soft Flow machine is the same as HTHP Soft flow Dyeing machine. The only difference is Atmospheric Soft Flow works at low temperatures & without pressure.

Some fabrics like Cotton & Cotton blends don’t require high temperatures. In that case, Soft Flow is very much suitable because Atmospheric Soft Flow reduces the running cost by saving energy. In short, it is a Cotton dyeing machine.

Furthermore, the liquor ratio of the Soft Flow machine is lower than that of the HTHP Soft Flow machine.

🔸 Technical Specification

✅ Lowest liquor ratio up to 1:4 (wet Fabric)

✅ Capacity: 50 to 1200 kg.

✅ Dye –30 To 500 Grms/Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

✅ Maximum Temprature – Up to 98° C.

✅ The vessel builds from stainless steel SS 316L Quality.➡ Online filter for easy clean-up even during the process with an extra filter mesh.

➡ For smooth fabric circulation, a Teflon Sheet is inside the chamber.

➡ Cup type very soft nozzle with low pressure & higher volume design.

➡ The fabric driving reel comes with a frequency controller.

SKU: D/ASF-1 -

Dyeing Machinery

Automatic Jigger

Automatic JIGGER is one of the best dyeing machine inventions for simplifying the dying process. Automatic JIGGER is a Hybrid of hydraulic & conventional JIGGER.

Automatic JIGGER comes with two types 1st one is OPEN TYPE & other one is CLOSE TYPE.

Where One-hand OPEN TYPE Automatic JIGGER comes with all the benefits like

✅ Auto tension control

✅ Auto speed control

✅ Auto cycle control

✅ Circulation system with filters to avoid centre to selvedge

✅ Suitable for any exhaust pre-treatment, dyeing & finish process

✅ Tension setting device to avoid running crease & machine jerks

⭕ Auto pendulum control (optional)

⭕ Batching or winch device (optional)

⭕ Auto water level controller (optional)

⭕ Pneumatic operated drain (optional)Otherhand CLOSE TYPE Automatic JIGGER comes with the additional features like

✅ Auto circulation system

✅ Auto temperature controller

✅ A fully covered jigger will save utilities

⭕ Dosing side tank facility (optional)

⭕ Circulation system with filters to avoid centre to narrow border (optional)The tension control system allows Automatic JIGGER to dye any fabric with ease. One operator can run four Automatic JIGGER machines simultaneously thanks to its PLC system, and the individual drive “automatic dyeing jigger” runs on zero tension on the fabric.

Automatic JIGGER uses both rollers powered by separate gearboxes and motors on inverter drives which do wonders for uniform dyes, even when running at varying speeds.

In conclusion, it is the best-woven dyeing machine, fabric dyeing machine or Cotton dyeing machine.

🔶 Technical Specification

✅ Capacity: 300 Kg. to 2000 kg. [OPEN]

✅ Capacity: 500 Kg. to 2000 kg. [CLOSE]

✅ Available Width: 1250mm to 3400mm

✅ S.S. Structure 304 Out Outer body 316 mail rolls plus inner bottom

✅ 0 to 10 Kgs. (Tension less operation Possible)

✅ Suitable for any Fabric from 30gsm to 500gsm

✅ S.S. Cladded Main Roll

✅ Pneumatic cylinders operated doors [CLOSE]

✅ Individual drive on each roller

✅Speed & tension control through a drive

SKU: n/a -

Dyeing Machinery

CP Dyeing

CP Dyeing

CP Dyeing is dyeing machinery to Dye Fabrics rapidly. Dye Fabric. This machine has the following features.

- First, it dyes the cloth with reactive colours. The CP Dyeing is installed with a small vat & shaped to allow fabrics an adequate contact time for absorbing dye bath through the high speed of cloth.

- In other words, CP Dyeing dyes the cloth rapidly, with less place required.

- Secondly, Reduced liquor volume is possible due to the fast exchange of fluid. Therefore, less wastage of resources.

- Thirdly, CP Dyeing‘s Roller width can be made from 1200mm to 3000mm depending on the client’s need.

🔶 Special Features:

✅ Versatile because it is equally suitable for Light and Heavy fabrics.

✅ Utilising of “Two Nip Two Dip” method ensures consistent colour penetration.

✅ The Top rubber roller is anti-deflecting construction.

✅ On Nips, pneumatic loading can be as much as 6 tons.

✅ Minimum loss of dye liquor because of low Dye liquor content in the trough.

✅ The main Batcher can batch cloth up to 1500mm Dia.

✅ Drive to both padder & Batcher by inverter-controlled AC Drive.

✅ Minimum tension between padder & Batcher is for perfect winding of cloth.

✅ The minimum distance between Padder & Batcher is to avoid oxidation.

✅ Machines are available from 1200mm to 3000mm roller width.

SKU: n/a -

Dyeing Machinery

HT.HP. Soft flow

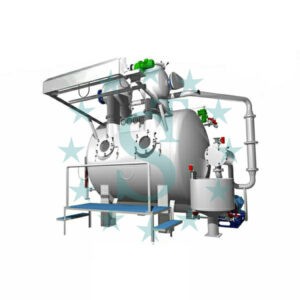

HTHP Soft flow

- First and foremost, HTHP Soft Flow Dyeing Machine is suitable for sensitive surface structures and natural fabrics. All fabrics like cotton, wool, viscose, acrylic and blends of jersey, terry towel, velour and nylon.

- Secondly, HTHP Soft Flow Machine is a contemporary technology that uses a curved nozzle to transfer the cloth smoothly at a high fluid flow. As a result, reduce strain and avoid creases and peeling.

- Thirdly, by the new design, HTHP Soft Flow takes the Lowest liquor ratio up to 1:5 (on wet material) instead of the conventional design taking the liquor ratio up to 1:10 (on wet).

- Fourthly, HTHP Soft Flow is made of high-quality steel inside and out, making it rust-resistant.

- Fifthly, the nozzles inside HTHP Soft Flow come with 316L Quality stainless steel. It gives smooth operation to the cloth.

- Lastly, HTHP Soft Flow includes numerous safety features.

In conclusion, it is perfect for modern textile dyeing plants.

🔸 Technical Specification

✅ Lowest liquor ratio up to 1:5 (wet Fabric)

✅ Capacity: 50 to 2000 kg.

✅ Dye –30 To 500 Grms/Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

✅ High Temp. – Up to 140° C.

✅ The vessel builds from stainless steel SS 316L Quality.➡ Online filter for easy clean-up even during the process with an extra filter mesh.

➡ For smooth fabric circulation, a Teflon Sheet is inside the chamber.

➡ Cup type very soft nozzle with low pressure & higher volume design.

➡ The fabric driving reel comes with a frequency controller.

SKU: D/HSF-1 -

Dyeing Machinery

HT.HP. Soft Over Flow

HTHP Soft Over Flow is just like the HTHP Soft Flow machine with a bigger capacity & for heavy fabrics.

HTHP Soft Over Flow is Specially Designed to process Heavy and sensitive fabrics like Terry Towel, and Curtain Bedsheet of 100% Cotton knit and woven fabrics. In short, it’s a Terry towel dyeing machine.

HTHP Soft Over Flow can work as a Soft Overflow with minor adjustments.

A larger nozzle diameter, with a Higher volume & low-pressure nozzle design and inside Teflon sheet are helpful to move the fabric very smoothly and gently without damaging the cloth.

A specially develop online filter design helps to collect the Terry towel fumes.

🔸 Technical Specification

✅ Capacity: 50 to 2000 kg.

✅ The process has a sensitive fabric like Terry Towels, Curtain, Bed Sheet, 100% cotton knit & woven etc.

✅ Work as Soft flow or as overflow dyeing.

✅ High Temp. – Up to 140 ° C.

✅ The vessel makes of stainless steel 316 L.

✅ Specially developed a filter to collect towel fumes.

✅ Teflon Sheet inside the chamber for smooth fabric movement.

✅ High volume, Low-pressure soft nozzle with a larger diameter for heavy and Larger width fabrics

✅ Fabric drive reel with frequency controller.

SKU: D/HSO-1 -

Dyeing Machinery

Hydraulic Jigger

Hydraulic Jigger

Hydraulic Jigger is a piece of revolutionary equipment for open-width Scouring, Bleaching & Dyeing processes in batch form. One of the best Dyeing machinery with perfect dyeing results. Hydraulic Jigger has the following features:

- Firstly, Hydraulic Jigger’s Adjustable tension according to Fabric quality ensures perfect pre-treatment and dyeing irrespective of run lengths for the same shade/colour. In other words, Hydraulic Jigger dyes the Clothing rapidly with accuracy.

- Secondly, Hydraulic Jigger comes with closed chambers with doors that close while the operation is performing. Which gives it desired temperature in less time. Therefore, less wastage of resources.

- Thirdly, Consistent dyeing of the same shade for any number of times in the future, Moreover the highly efficient washing system saves washing time and precious Water. The uniform tension, process time, and ideal temperature contribute to the dying quality.

- Fourthly, Hydraulic Jigger controls these parameters resulting in fully controllable and reproducible shades. The controlled temperature and a steady circulation of dye liquid for flawless dyeing. PLC aided operation for repeatability. Suiting, shirting, and delicate fabrics such as rayon are best suited.

- Fifthly, the Hydraulic Jigger is available in 500kg and 1000kg capacity from 1200mm to 3000mm working width depending on the client’s need. Fabric ranging from 70 to 700 gsm/meter square of woven material may be dyed in a Hydraulic Jigger, making it ideal for Suiting, Shirting, and Delicate textile such as rayon.

Above all, flawless synchronisation of linear speed results in tension-free and crease-free fabric conveyance throughout the process.

🔸 Technical Specification

➡ Automatic reversal at the end of each cycle setting

➡ Spray washing through a selector switch

➡ Stopping the machine at the pre-determined sampling point

➡ Water filling through rotary switch

➡ Drain through a selector switch

➡ Digital Speed indication

➡ Speed setting through P L C

➡ Replenishing from dosing tank through valve

➡ Indirect steam heating through Heat Exchanger

➡ Temperature Controller.

➡ A valve adjusts the tension on the cloth.

➡ Soft Start & Stop

➡ Pendulation when adding and emptying liquid

➡ Touch Screen

➡ Specially designed software for the machine

SKU: n/a -

Dyeing Machinery

Jigger

Fabric dyeing machines can come in all shapes and sizes, but

A Jigger is typically an open-framed machine with a rotating drum that holds the fabric to be dyed. Jigger is the standard and oldest way to dye cotton and cotton blend fabric.

The jigger machine has been used for a long time to treat small to medium size lots of woven fabric with an open-width exhaust dyeing process. Dye jiggers are available in Two variants 1st Jigger is an Open type with the following options:

✅ Fully S.S. construction or Mounted on C.I. Walls.

✅ With a water re-circulation system and temperature controllers.

✅ A.C. Motor drive or Inverter Control Drive

✅ Semi Automatic or Fully Automatic

✅ S.S. Cladded Batch Rollers of Ebonite coated Batch Rollers2nd one is a Close type with the following advancement:

✅ Gear Box Type Semi Automatic Maxi Jigger Machine

✅ S.S. Spring Type Floating Device

✅ Roof Heating is Provided to Prevent Dropping on Fabrics

✅ Direct & Indirect Heating with Temperature Controller

✅ Auto R/F System with Cycle Contrail with the help of PLC

⭕ Pneumatic Operated Auto Drain (Optional)

⭕ A Direct Mounted Reduction Gear Box (Optional)🔸 Technical Specification

✅ The Machines are available from 1250mm to 3400mm in width

✅ Roll Center: 25″, 31″, 36″, 41″

✅ Complete Stainless Steel Body with M.S. Base Frame

✅ Capacity: 225 Kg., 350 Kg., 500 Kg., 750Kg., 1000Kg., 1500Kg.(250 Gsm)

✅ Complete Stainless Steel Body.

✅ Heavy-duty brake drum.

✅ Heavy duty differential Gear unit.

✅ A.C. Frequency Drive.

✅ Stainless Steel Cladded Main Roll

✅ Circulation System with 2.0 H.P.In conclusion, This is best for small batches to mass dyeing lots with the durable built of Stainless Steel it gives durability instead of the lower model. The water re-circulation system makes accurate dyeing results while keeping the fabric clean. Heavy-duty brake drums give precise tension to the cloth with the help of an A.C. Frequency drive.

In short, It is the basic necessity for a small dyeing house to a large dyeing industry with less space and higher capacity. It is the Best Fabric Dyeing machine for small to medium size cotton dyeing units.

SKU: jigger -

Dyeing Machinery

Long Tube Jet

Long tube Jet dyeing machine working concept is same compare with Convention Rapid long tube jet dyeing machine. Though the major advantage of this machine is liquor ration is nearly half than conventional rapid Jet dyeing machine. In this machine fabric does not float but it run nearly in dry condition. Another benefit of this machine is it’s single vessel with two chamber design. Due to this design fabric loop length is reduce additionally bringing down the running cost, capital cost as well as processing time.

[spbsm-follow-buttons]

SKU: n/a -

Dyeing Machinery

Multi-Nozzle Soft flow

Multi-Nozzle Soft Flow is a Low/High-Temperature dyeing machine technology that works as a “Soft flow” or as a “Jet dyeing” machine.

The main advantage of this development is to increase the machine’s flexibility and versatility to process all types of fabrics.

The soft nozzles in this new technological advancement have a large diameter, and the fixed nozzle has an individual flow control valve, whereas the main nozzle is adjustable.

By increasing and decreasing the gap of a nozzle, flow and pressure increase or decrease as per fabric quality demand.

To run Multi-Nozzle Soft Flow as a soft flow machine, increase the gap Which, subsequently decreases the pressure and increases water flow,

At the time, all three nozzles worked as Soft flow & water flow gets controlled individually by the control valve As per fabric quality demand.

To run The Multi-Nozzle Soft Flow as a “Jet dyeing” Machine lowering the gap of a nozzle which increases the pressure and decreases the water flow. That time close the soft-nozzle control valve.

🔸 Technical Specification

✅ Capacity: 25 to 400 kg. (Single Tube)

✅ Ultra Low Liquor Ratio – 1:1 (Wet Fabric)

✅ Dye –30 To 500 Grms./Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

✅ High Temp. – Up to 140° C.

✅ Max. Fabric Speed – 400 Mtr./Min.

✅ Work as a Jet Dyeing or as Soft flow to meet the requirements of all types of fabric quality.

✅ Vessel: SS 316 L.

✅ Multiple soft nozzles.

SKU: D/MSF-1 -

Dyeing Machinery

Regular Jet

Regular Jet dyeing

This machine is best for polyester fabric dyeing cause it runs on a high pressure of high-temperature water. Regular Jet dyeing is economical because the low liquor ratio reduces everything.

The fabric inside this polyester dyeing machine moves solely due to the force of water.

It is user-friendly because, If we compare it with a Long tube dyeing machine. Four valves are necessary to control the fabric’s motion. Here in Regular Jet dyeing, there is only one valve.

Absent of reel, reduce connecting electric power, maintenance of two mechanical seals and breakdown time if Jet pressure and reel speed are not synchronized.

Nearly 4000 without fabric drive reel devices are saving energy and lowering pollution in 20 countries.

🔸 Technical Specification

✅ Capacity: 25 to 400Kg.(Single Tube)

✅Ultra Low Liquor Ratio – 1:1 (Wet Fabric)

✅ Dye – 30 To 450 Grms./Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

✅ High Temp. – Up to 140 ° C.

✅ Fabric Speed – 300 Mtr./Min.

✅ Vessel: SS 316 LBest Polyester dyeing machine with a low liquor ratio in a Jet dyeing form.

SKU: D/JD-1 -

Dyeing Machinery

Semi Automatic Jigger Machine

Semi Automatic Dyeing Jigger

Roll Center 31″ (790 mm) – 36″ (915mm)

Capacity 350-500 Kg. (250 gsm)

Batch Dia 900-1100 mm

Available Width : 48″ To 150″ Roller WidthSemi Automatic Jumbo Jigger Machine

Roll Center 31″ (790 mm) – 36″ (915mm)

Capacity 350-500 Kg. (250 gsm)

Batch Dia 900-1100 mm

Available Width : 48″ To 150″ Roller Width[spbsm-follow-buttons]

SKU: n/a -

Dyeing Machinery

Top Tube Soft Flow

Top Tube Soft flow dyeing machine very much suitable to process delicate woven & knitted fabrics. It’s soft nozzle decrease tension further avoid problems like crease marks, rope marks, shrinking etc.

Another benefit of this machine is its single vessel two chamber design reduce fabric loop length as well as processing time.

[spbsm-follow-buttons]

SKU: n/a