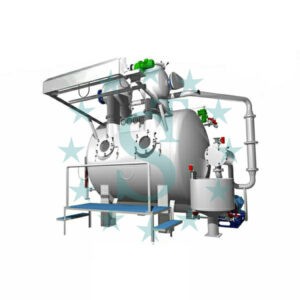

Stenter

The Stenter or Hot air Stenter Machine is one of the Fabric Finishing Machines like Relax Dryer whose heat set capabilities give the fabric the final result of all the processes it went through.

Stenter has detachable nozzle fingers that are easy to clean and sliding filters which remove lint as they come out.

It also comes with an A.C. inverter system that allows the operator to make changes as needed within seconds.

Stenter comes with the following advance and improved features:

🔶 Higher Production Speeds

✅ Use of elongated oval Nozzle slits for higher air velocity.

✅ The lowest gap between the top and bottom Nozzle faces prevents the drop in enthalpy.

✅ High-energy blower fans displace high volumes of air.

✅ Fabric working width can be customised from 1600mm to 3400mm and cambers from 1 to 12 depending on customer need.

✅ Speed From 40 to 100 meters per minute by A.C. Inverter System.

🔶 Efficiency

✅ Double-jacketed sealed provides the best insulation.

✅ Seasoned cast iron lubricated rail provides friction-free movement of the chain.

✅ All pipelines are installed inside the machine to cut out conduction losses.

✅ Give 15% More Saving against other stenter.

🔶 Maintenance

✅ Detachable Nozzle fingers for easy cleaning & Online sliding filters for lint removal make it easy to maintain on daily bases.

✅ Online sliding filters for lint removal.

✅ Easy access inside chambers for observation.

✅ Advanced chamber technology makes it easy to install and reinstall if needed without interfering with the performance.

Working width decides upon the maximum width of fabric & chambers decide upon the maximum per day production requires.

As its Fabric Finishing machine, Stenter can finish fabric like Hosiery, Cotton, Polyester, Cotton Hosiery, Polyester Hosiery, Polyester Cotton, Wool, Mink Blanket, Polar and Many more Knitted as well as woven fabrics.

In Conclusion, this machine is best for Dyeing and Printing Plants.

₹3,000,000.00

CompareStenter

The Stenter is one of the Fabric Finishing Machines like Relax Dryer whose heat set capabilities to give the fabric the final result of all the processes it went through. Stenter has detachable nozzle fingers that are easy to clean and sliding filters which remove lint as they come out. Stenter also comes with an A.C. inverter system that allows the operator to make changes as needed within seconds.

Stenter comes with the following advance and improved features:

🔶 Higher Production Speeds

✅ Use of elongated oval Nozzle slits for higher air velocity.

✅ The lowest gap between the top and bottom Nozzle faces prevents the drop in enthalpy.

✅ High-energy blower fans displace high volumes of air.

✅ Fabric working width can be customised from 1600mm to 3400mm and cambers from 1 to 12 depending on customer need.

✅ Speed From 40 to 100 meters per minute by A.C. Inverter System.

🔶 Efficiency

✅ Double jacketed sealed provides the best insulation.

✅ Seasoned cast iron lubricated rail provides friction-free movement of the chain.

✅ All pipelines are installed inside the machine to cut out conduction losses.

✅ Give 15% More Saving against other stenter.

🔶 Maintenance

✅ Detachable Nozzle fingers for easy cleaning & Online sliding filters for lint removal make it easy to maintain on daily bases.

✅ Online sliding filters for lint removal.

✅ Easy access inside chambers for observation.

✅ Advance chamber technology makes it easy to install and reinstall if needed without interfering with the performance.

Working width decides upon the maximum width of fabric & chambers decide upon the maximum per day production requires.

As its Fabric Finishing machine, Stenter can finish fabric like Hosiery, Cotton, Polyester, Cotton Hosiery, Polyester Hosiery, Polyester Cotton, Wool, Mink Blanket, Polar and Many more Knitted as well as woven fabrics.

In Conclusion, this machine is best for Dyeing and Printing Plants.

1. Select Product

Choose the required specification & submit the details.

2. Get Offer

Get a Detailed Offer.

3. Pay The Advance

Pay the advance amount as per agreed terms.

4. Product Under Construction

Product goes under Construction according agreed time.

5. Pay The Rest Amount

Pay the balance amount as your machine get ready to dispatch.

6. Shipment Initiated

Shipment option available through Manufacturer.

7. Installation

Finally, the product will be installed at your plant.

Stenter | Fabric Finishing Machine | Book 1 to 12 Chambers | Accurate

purpose of the stenter or hot air machine is to heat setting the fabric and to stretch it's width wise to recover the uniform width. It comes with customize sizes.

Product SKU: F/S-1

Product Brand: Indian

Product Currency: ₹

Product Price: 3000000

Price Valid Until: 2023-08-01

Product In-Stock: PreOrder

5

| Fabric | Hosiery, Cotton, Polyester, Cotton Hosiery, Polyester Hosiery, Polyester Cotton, Wool, Mink Blanket, Polar |

|---|---|

| Fabric Width | 1600mm, 1800mm, 2400mm, 2600mm, 2800mm, 3000mm, 3200mm, 3400mm |

| Chambers | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 |

Stenter | Fabric Finishing Machine | Book 1 to 12 Chambers | Accurate

purpose of the stenter or hot air machine is to heat setting the fabric and to stretch it's width wise to recover the uniform width. It comes with customize sizes.

Product SKU: F/S-1

Product Brand: Indian

Product Currency: ₹

Product Price: 3000000

Price Valid Until: 2023-08-01

Product In-Stock: PreOrder

5

Youtube

Coming Soon

Stenter | Fabric Finishing Machine | Book 1 to 12 Chambers | Accurate

purpose of the stenter or hot air machine is to heat setting the fabric and to stretch it's width wise to recover the uniform width. It comes with customize sizes.

Product SKU: F/S-1

Product Brand: Indian

Product Currency: ₹

Product Price: 3000000

Price Valid Until: 2023-08-01

Product In-Stock: PreOrder

5

Based on 0 reviews

Be the first to review “Stenter”

-

Dyeing Machinery

Atmospheric Soft Over Flow

Atmospheric Soft flow

The Atmospheric Soft Flow machine is the same as HTHP Soft flow Dyeing machine. The only difference is Atmospheric Soft Flow works at low temperatures & without pressure.

Some fabrics like Cotton & Cotton blends don’t require high temperatures. In that case, Soft Flow is very much suitable because Atmospheric Soft Flow reduces the running cost by saving energy. In short, it is a Cotton dyeing machine.

Furthermore, the liquor ratio of the Soft Flow machine is lower than that of the HTHP Soft Flow machine.

🔸 Technical Specification

✅ Lowest liquor ratio up to 1:4 (wet Fabric)

✅ Capacity: 50 to 1200 kg.

✅ Dye –30 To 500 Grms/Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

✅ Maximum Temprature – Up to 98° C.

✅ The vessel builds from stainless steel SS 316L Quality.➡ Online filter for easy clean-up even during the process with an extra filter mesh.

➡ For smooth fabric circulation, a Teflon Sheet is inside the chamber.

➡ Cup type very soft nozzle with low pressure & higher volume design.

➡ The fabric driving reel comes with a frequency controller.

SKU: D/ASF-1 -

Finishing Machinery

Denim Finishing Range

Denim Finishing Range

The Denim Finishing Range Exclusive purpose is to ensure that the garment made from such fabric does not shrink after the wash hence perfect dimensional stability.

As per standard, + / -1 % residual shrinkage is acceptable. Denim Finishing Range is available for up to 3600mm working width fabric to assure total shrinkage protection to Denim fabrics.

Denim Finishing Range was developed in a way that can shrinkage up to 14% in a single passage.

Denim Finishing Range is usually the last process in the sequence of fabric finishing. The Denim fabric processed in Denim Finishing Range gets fully shrunk.

Before Denim Finishing Range, it is advisable to establish the width at which the cloth should get shrunk in length to meet the requirement of the garment makers. It is the best Fabric Finishing machinery.

🔸 Key Features:

✅ Ensuring Required Shrinkage of 14 Ounce Denim in Single RUN At a Speed of 40 to 50 Mtrs / Min.

✅ Matching all parameters of Shrinkage, Feel, Warp & Weft Tension.

✅ Complete Machine with P.L.C. Controlled Inverter Drive.

✅ Large Touch Screen, Showing Shrinkage, Speed and Other Data, Minimum Usage, of Steam & Power.

✅ User-friendly machine with the shortest Payback time.

✅ Can finish lycra fabrics in a single run with required weft and warp shrinkage at the speed of 40 mt / min.

✅ Specially designed heavy warp pull to control the width of the fabric and warp stretch control by P L C.

✅ Motorized antiskew device to control the skew setting of fabric twill by forwarding and reversing the movement of motors.

✅ Specially developed a shrinking unit to achieve shrinkage up to 14 % depending upon the quality of the fabric with residual shrinkage of 1 %.

✅ 2500mm dia Mirror polished Jacketed main palmer cylinder with rotary joints.

✅ The number of 2 cooling cylinders is provided at the exit of the palmer unit to cool down the fabrics.

⭕ Singing unit at the feeding side. (Optional)

⭕ Brushing unit at feeding side. (Optional)

⭕ Temperature controlling of shrinkage and palmer unit by PLC. (Optional)

⭕ Big Batching device with ‘J’ scray at plating side. (Optional)

SKU: F/DFR-1 -

Burner, Heating Solution

Burner 200 – Stage 2

Burner 200 | Heating solution

The Gas Burner 200 is a heating solution for small-medium appliances. The gas burner can be used as either a primary or secondary heating source, offering great versatility to users. It is designed not only to be functional but also beautiful.

We designed this, will ensure you have a high-efficiency, energy-efficient heating solution.

The gas burner was created as a way of providing an aesthetically pleasing solution for companies looking for a simpler alternative.

Benefits

✅ Modern design

✅ Efficient

✅ Aesthetic

✅ Environmentally friendly

✅ Reduces air pollution because it reduces wood consumption by up to 5 times

✅ Tangential Ventilation

✅ Heats quickly and efficiently

SKU: n/a -

Accessories

A Frame

A-FRAME Trolley

A-Frame trolley is one of the most required Accessories in Textile Plant and Mills. A-frame’s objective is to carry the fabric and make it easy to manoeuvre inside the facility while different processes such as measuring, washing, cleaning, dyeing or printing, and finishing.

A-frame trolleys are also Utilised in rotating stations by simply adding an extension to them.

A-frame trolleys come in different sizes from 44 to 130 inches roller width depending on the customer. A-frame trolleys take less space than bucket/box-type trolleys. It gets easier to manage them and store them in one place.

Inshot A-Frame Tolleys are best to manage and store the grey to finished material in a clean and sorted way that helps to identify the fabric lot.

Many Textile mills and Export houses have been using it for a long time, making it reliable and one of the solutions to manage the fabric.

🔸 Technical Specification

✅ A FRAME’s top roll fabricate from M.S. Seamless Pipe (Ebonite quoting).

✅ The end shaft is RIB constructed or As per the buyer’s suggestion.

⭕ Cladding of S.S. Sheet on a batch roll. (Optional)

✅ The front side pooling system is a swivel-type M.S. fabricated bracket with 10″ x 2 wheels.

✅ The rare side is of fixed type 12″ x 3″ wheel.

✅ Batch coupling is fit on a batch roll for rotating.

✅ A-FRAME is manufactured from an M.S. channel (100/50mm) x 6mm wall thickness.

SKU: A/T-1 -

Dyeing Machinery

HT.HP. Soft Over Flow

HTHP Soft Over Flow is just like the HTHP Soft Flow machine with a bigger capacity & for heavy fabrics.

HTHP Soft Over Flow is Specially Designed to process Heavy and sensitive fabrics like Terry Towel, and Curtain Bedsheet of 100% Cotton knit and woven fabrics. In short, it’s a Terry towel dyeing machine.

HTHP Soft Over Flow can work as a Soft Overflow with minor adjustments.

A larger nozzle diameter, with a Higher volume & low-pressure nozzle design and inside Teflon sheet are helpful to move the fabric very smoothly and gently without damaging the cloth.

A specially develop online filter design helps to collect the Terry towel fumes.

🔸 Technical Specification

✅ Capacity: 50 to 2000 kg.

✅ The process has a sensitive fabric like Terry Towels, Curtain, Bed Sheet, 100% cotton knit & woven etc.

✅ Work as Soft flow or as overflow dyeing.

✅ High Temp. – Up to 140 ° C.

✅ The vessel makes of stainless steel 316 L.

✅ Specially developed a filter to collect towel fumes.

✅ Teflon Sheet inside the chamber for smooth fabric movement.

✅ High volume, Low-pressure soft nozzle with a larger diameter for heavy and Larger width fabrics

✅ Fabric drive reel with frequency controller.

SKU: D/HSO-1 -

Burner, Heating Solution

Burner 550 – Stage 3

Burner 550 | Heating solution

This heating solution burner 550 comes to volume, potential, and cost efficiency. The Burner 550 is a series stage 3 covers output ranges under 80mg/kWh. These gas burners were designed with an advanced combusting head which provides consistent combustion even under difficult working conditions.

The placement of the components inside the burner permits easy and precise regulation and maintenance.

Benefits

🔥 Amazingly efficient at burning gas

🔥 Stable flame no matter what kind of weather you’re dealing with

🔥 High efficiency (80mg/kWh)

🔥 Efficient, clean combustion

🔥 Power is increased without complications✅ Easy to maintain

✅ Great energy savings

SKU: n/a

There are no reviews yet.