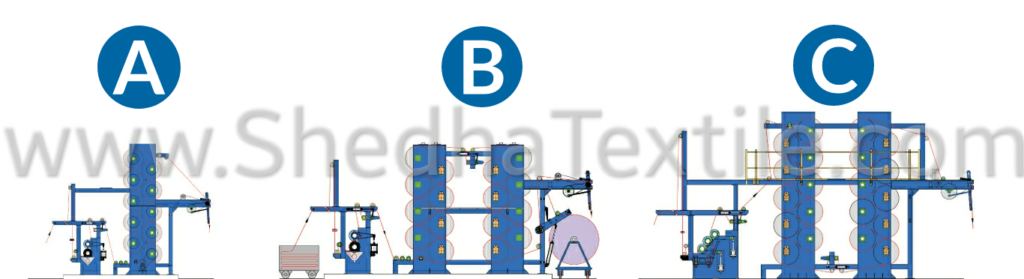

Compressive Shrinking Range

The Sole purpose of the Controlled Compressive Shrinking Range or ZEROZERO is to ensure that the garment made from such fabric does not shrink after the wash hence perfect dimensional stability.

As per standard, + / -1 % residual shrinkage is acceptable. Controlled Compressive Shrinking Range or ZEROZERO are available up to 3200mm working width fabric to assure total shrinkage protection to woven fabrics. It can be 100% cotton, cotton/polyester, cotton/viscose or tough and heaviest fabric like denim. Compressive Shrinking Range or ZEROZERO developed in a way that can shrinkage up to 12% in a single passage.

The most capable of shrinking medium, lightweight fabric to the heaviest denim, cotton blended suiting & shirting by watering cotton, terylene, hemp and its blends to shrink the cloth to meet the requirements of shrinkage, stabilization and improve the hand touch.

A controlled Compressive Shrinking Range is usually the last process in the sequence of fabric finishing. The woven fabric processed in the machine gets fully shrunk.

Before compressive shrinking, it is advisable to establish the width at which the cloth should get shrunk in length to meet the requirement of the garment makers. It is the best Fabric Finishing machinery.

🔸 Technical Specification

✅ A.C. frequency conversion transmission, designed speed: 10-80m/minute.

✅ Shrinkage 0 – 12 % depending upon fabric quality.

✅ Minimum and controlled tension.

⭕ Imported Rubber Blanket and Polyester Felt will be provided optionally.

✅ A Jacketed drum in 1500mm, 2000mm and 2500mm diameters.

✅ Stainless Steel damping & conditioning unit supplied as standard Parts.

₹2,500,000.00

CompareCompressive Shrinking Range

The Sole purpose of Controlled Compressive Shrinking Range or ZEROZERO is to ensure that the garment made from such fabric does not shrink after the wash hence perfect dimensional stability.

As per standard, + / -1 % residual shrinkage is acceptable. Controlled Compressive Shrinking Range or ZEROZERO are available up to 3200mm working width fabric to assure total shrinkage protection to woven fabrics. It can be 100% cotton, cotton/polyester, cotton/viscose or tough and heaviest fabric like denim. Compressive Shrinking Range or ZEROZERO developed in a way that can shrinkage up to 12% in a single passage.

The most capable of the shrinking medium, lightweight fabric to the heaviest denim, cotton blended suiting & shirting by watering cotton, terylene, hemp and its blends to shrink the cloth to meet the requirements of shrinkage, stabilization and improve the hand touch.

A controlled Compressive Shrinking Range is usually the last process in the sequence of fabric finishing. The woven fabric processed in the machine gets fully shrunk.

Before compressive shrinking, it is advisable to establish the width at which the cloth should get shrunk in length to meet the requirement of the garment makers.

🔸 Technical Specification

✅ A.C. frequency conversion transmission, designed speed: 10-80m/minute.

✅ Shrinkage 0 – 12 % depending upon fabric quality.

✅ Minimum and controlled tension.

⭕ Imported Rubber Blanket and Polyester Felt will be provided optionally.

✅ A Jacketed drum in 1500mm, 2000mm and 2500mm diameters.

✅ Stainless Steel damping & conditioning unit supplied as standard Parts.

🔸 Payment, Taxes and Delivery

Payment: Before dispatch of machinery, 40% advance and a balance against the proforma invoice.

Delivery: Delivery of machine ideally comes within 4 to 6 weeks.

Freight: Will be paid by the customer.

Sales Tax: GST 18% (Domestic Orders) Or Vat 4% +1% No CST against form “H”( export orders).

Installation: Will be charged extra per machine over and above the price.

1. Select Product

Choose the required specification & submit the details.

2. Get Offer

Get a Detailed Offer.

3. Pay The Advance

Pay the advance amount as per agreed terms.

4. Product Under Construction

Product goes under Construction according agreed time.

5. Pay The Rest Amount

Pay the balance amount as your machine get ready to dispatch.

6. Shipment Initiated

Shipment option available through Manufacturer.

7. Installation

Finally, the product will be installed at your plant.

Controlled Compressive Shrinking Range | Fabric finishing | best shrinkage up to 12%

Controlled Compressive Shrinking Range is to ensure that the garment made from such fabric does not shrink after wash hence perfect dimensional stability.

Product SKU: F/CSR-1

Product Brand: Indian

Product Currency: ₹

Product Price: 2500000

Price Valid Until: 2023-08-01

Product In-Stock: PreOrder

5

| Machine width | 1600mm, 1800mm, 2000mm, 2200mm, 2400mm, 2600mm, 2800mm, 3000mm, 3200mm |

|---|---|

| Jacketed drum Dia | 1500mm, 2000mm, 2500mm |

Controlled Compressive Shrinking Range | Fabric finishing | best shrinkage up to 12%

Controlled Compressive Shrinking Range is to ensure that the garment made from such fabric does not shrink after wash hence perfect dimensional stability.

Product SKU: F/CSR-1

Product Brand: Indian

Product Currency: ₹

Product Price: 2500000

Price Valid Until: 2023-08-01

Product In-Stock: PreOrder

5

Based on 0 reviews

Be the first to review “Compressive Shrinking Range”

-

Dyeing Machinery

Hydraulic Jigger

Hydraulic Jigger

Hydraulic Jigger is a piece of revolutionary equipment for open-width Scouring, Bleaching & Dyeing processes in batch form. One of the best Dyeing machinery with perfect dyeing results. Hydraulic Jigger has the following features:

- Firstly, Hydraulic Jigger’s Adjustable tension according to Fabric quality ensures perfect pre-treatment and dyeing irrespective of run lengths for the same shade/colour. In other words, Hydraulic Jigger dyes the Clothing rapidly with accuracy.

- Secondly, Hydraulic Jigger comes with closed chambers with doors that close while the operation is performing. Which gives it desired temperature in less time. Therefore, less wastage of resources.

- Thirdly, Consistent dyeing of the same shade for any number of times in the future, Moreover the highly efficient washing system saves washing time and precious Water. The uniform tension, process time, and ideal temperature contribute to the dying quality.

- Fourthly, Hydraulic Jigger controls these parameters resulting in fully controllable and reproducible shades. The controlled temperature and a steady circulation of dye liquid for flawless dyeing. PLC aided operation for repeatability. Suiting, shirting, and delicate fabrics such as rayon are best suited.

- Fifthly, the Hydraulic Jigger is available in 500kg and 1000kg capacity from 1200mm to 3000mm working width depending on the client’s need. Fabric ranging from 70 to 700 gsm/meter square of woven material may be dyed in a Hydraulic Jigger, making it ideal for Suiting, Shirting, and Delicate textile such as rayon.

Above all, flawless synchronisation of linear speed results in tension-free and crease-free fabric conveyance throughout the process.

🔸 Technical Specification

➡ Automatic reversal at the end of each cycle setting

➡ Spray washing through a selector switch

➡ Stopping the machine at the pre-determined sampling point

➡ Water filling through rotary switch

➡ Drain through a selector switch

➡ Digital Speed indication

➡ Speed setting through P L C

➡ Replenishing from dosing tank through valve

➡ Indirect steam heating through Heat Exchanger

➡ Temperature Controller.

➡ A valve adjusts the tension on the cloth.

➡ Soft Start & Stop

➡ Pendulation when adding and emptying liquid

➡ Touch Screen

➡ Specially designed software for the machine

SKU: n/a -

Dyeing Machinery

Semi Automatic Jigger Machine

Semi Automatic Dyeing Jigger

Roll Center 31″ (790 mm) – 36″ (915mm)

Capacity 350-500 Kg. (250 gsm)

Batch Dia 900-1100 mm

Available Width : 48″ To 150″ Roller WidthSemi Automatic Jumbo Jigger Machine

Roll Center 31″ (790 mm) – 36″ (915mm)

Capacity 350-500 Kg. (250 gsm)

Batch Dia 900-1100 mm

Available Width : 48″ To 150″ Roller Width[spbsm-follow-buttons]

SKU: n/a -

Processing Machinery

Desizing Machine

Desizing machine

Desizing is the process of removing the size applied during weaving. The purpose of this fabric processing machinery Desizing machine is to remove the sizing ingredients such as starches, gums, PVA etc.

The starch has to be degraded into less water-soluble molecules by hydrolysis. The hydrolysis of starch using enzymes under particular concentration, temperature and duration is called desizing.

Desizing can do at room temperature to boiling temperature as per the quality of the enzyme.

Desizing Tank is made from Stainless Steel material. The tank can have open or fully enclosed construction as per requirement. The number of rollers in the tank facilitates suitable liquor takeup of every kind of fabric which is to be desized.

Desizing machine speed can be lowered or raised for proper take-up of the liquor for different grades of cloth.

🔸 Key Functions:

✅ 5 to 60Mtrs/Min operational speed.

⭕ Automatic or manual dozing system (Optional)

✅ Auto Steam Control.

✅ Easy usage.

⭕ Chemical preparation tanks (Optional)

✅ Desizing machines are available from 1600mm to 3400mm fabric width.

SKU: P/DM-1 -

Processing Machinery

Polymeriser

Polymeriser

Polymeriser is to use for fixing printed garments. Polymeriser is an Important part of Processing machinery cause it secures the colour before the washing and finishing. There are the following features in it.

- Firstly, Polymeriser assures perfect fixation of dyes even at higher temperatures. In other words, the Dyes can be permanent before starting the washing and finishing process of the cloth.

- Secondly, It is most suitable for curing Phthalein dye, Pigments, and resin set.

- Thirdly, Pre-dryer removes gaseous fumes from printed fabrics – an exclusive speciality of this Machine. The Machine operates efficiently in the temperature range from 30ºC Temperature to 180ºC and ensures automatic regulation of temperatures within the chamber.

- Fourthly, the width can be made from 1600mm to 3200mm as per the client’s need.

- Fifthly, Garment weighted from 70 to 700 gsm/per meter square can be processed.

- The sixth and most Importantly speed can be achieved up to 40 meters per minute while performing the process.

In conclusion, Polymeriser is best suitable for the garment industry or dyeing & printing plants.

🔸 ADVANTAGES :

➡ Supply with hot air jets, recirculating fans and steam or thermic oil heating for best curing result.

➡ Separate blowers for top and bottom air nozzles.

➡ Its uniformity in temperature, width-wise, length and diagonally.

➡ No dropping by condensation.

➡ Variable speed up to 40 meters per minute by A.C. Inverter System.

➡ It is available in 60 to 150 meters of cloth content curing zone.

SKU: P001 -

Washing Machinery

Rope Washing Range

Rope Washing Range

Rope Washing Range is a fabric washing machine. Therefore, The Rope Washing Range is for woven fabrics like cotton, cotton/viscose, cotton/polyester or linen and knitted fabrics.

Viscose washed in rope form because of its poor wet strength.

Similarly, Knit fabrics tend to elongate in open form and require many holding gadgets. So, it is washed in rope form to avoid curling and elongation.

The Rope Washing Rang has two open-width compartments/triple drum compartment/cage washer for wetting and swelling dyes as well gum paste, fabric then gathered in a J-scray before going into the winch washing compartments.

The oval-type S.S. winch helps in thrashing the cloth into the S.S. washing tank to remove the gum and excessive colour.

There is a provision for heating the water with steam for faster removal of excessive materials. Long dwell times, controlled temperature and liquor flow to suit individual requirements add high washing efficiency.

Each tank can hold 110 kilos to 200 kilogrammes of cloth, depending on the breadth of the tank. After being washed with a rope opening mechanism, the fabric takes on an open state.

🔶 ADVANTAGES :

✅ Excellent washing efficiency.

✅ Sturdy construction.

✅ Low energy consumption.

✅ Quiet running.

✅ Lowest maintenance effort.

✅ Speed up to 70 Meters / Min.

✅ Easy installation

SKU: n/a

There are no reviews yet.