CP Dyeing

CP Dyeing

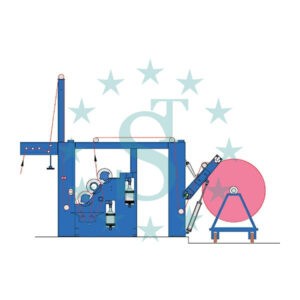

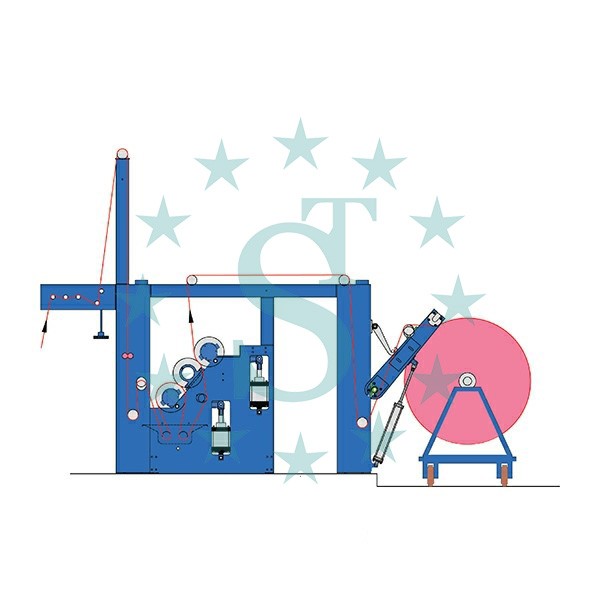

CP Dyeing is dyeing machinery to Dye Fabrics rapidly. Dye Fabric. This machine has the following features.

- First, it dyes the cloth with reactive colours. The CP Dyeing is installed with a small vat & shaped to allow fabrics an adequate contact time for absorbing dye bath through the high speed of cloth.

- In other words, CP Dyeing dyes the cloth rapidly, with less place required.

- Secondly, Reduced liquor volume is possible due to the fast exchange of fluid. Therefore, less wastage of resources.

- Thirdly, CP Dyeing‘s Roller width can be made from 1200mm to 3000mm depending on the client’s need.

🔶 Special Features:

✅ Versatile because it is equally suitable for Light and Heavy fabrics.

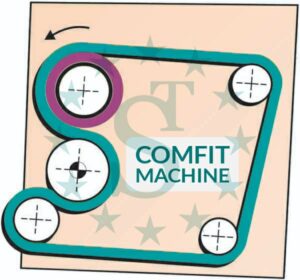

✅ Utilising of “Two Nip Two Dip” method ensures consistent colour penetration.

✅ The Top rubber roller is anti-deflecting construction.

✅ On Nips, pneumatic loading can be as much as 6 tons.

✅ Minimum loss of dye liquor because of low Dye liquor content in the trough.

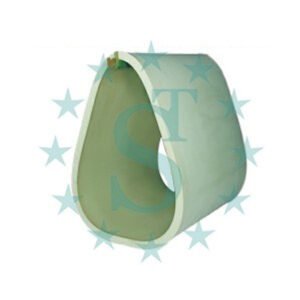

✅ The main Batcher can batch cloth up to 1500mm Dia.

✅ Drive to both padder & Batcher by inverter-controlled AC Drive.

✅ Minimum tension between padder & Batcher is for perfect winding of cloth.

✅ The minimum distance between Padder & Batcher is to avoid oxidation.

✅ Machines are available from 1200mm to 3000mm roller width.

₹1,450,000.00

CompareCP Dyeing

CP Dyeing is to use Dye Fabric. This machine has the following features.

- First, it dyes the cloth with reactive colours. The CP Dyeing is installed with a small vat & shaped to allow fabrics an adequate contact time for absorbing dye bath through the high speed of cloth.

- In other words, CP Dyeing dyes the cloth rapidly, with less place required.

- Secondly, Reduced liquor volume is possible due to the fast exchange of fluid. Therefore, less wastage of resources.

- Thirdly, CP Dyeing‘s Roller width can be made from 1200mm to 3000mm depending on the client’s need.

🔶 Special Features:

✅ Versatile because it is equally suitable for Light and Heavy fabrics.

✅ Utilising of “Two Nip Two Dip” method ensures consistent colour penetration.

✅ The Top rubber roller is anti-deflecting construction.

✅ On Nips, pneumatic loading can be as much as 6 tons.

✅ Minimum loss of dye liquor because of low Dye liquor content in the trough.

✅ The main Batcher can batch cloth up to 1500mm Dia.

✅ Drive to both padder & Batcher by inverter-controlled AC Drive.

✅ Minimum tension between padder & Batcher is for perfect winding of cloth.

✅ The minimum distance between Padder & Batcher is to avoid oxidation.

✅ Machines are available from 1200mm to 3000mm roller width.

🔸 Payment, Taxes and Delivery

Payment: Before dispatch of machinery, 40% advance and a balance against the proforma invoice.

Delivery: Delivery of machine ideally comes within 4 to 6 weeks.

Freight: Will be paid by the customer.

Sales Tax: GST 18% (Domestic Orders) Or Vat 4% +1% No CST against form “H”( export orders).

Installation: Will be charged extra per machine over and above the price.

|

1. Select Product

Choose the required specification & submit the details.

2. Get Offer

Get a Detailed Offer.

3. Pay The Advance

Pay the advance amount as per agreed terms.

4. Product Under Construction

Product goes under Construction according agreed time.

5. Pay The Rest Amount

Pay the balance amount as your machine get ready to dispatch.

6. Shipment Initiated

Shipment option available through Manufacturer.

7. Installation

Finally, the product will be installed at your plant.

CP Dyeing | Fabric Dyeing Machine | 48 to 120" Roller Face | Best for rapid dyeing

CP Dyeing is use for dyeing fabric with reactive colors.The machine is installed with a small vat & shaped to allow fabrics an adequate contact time

Product SKU: D/CP-1

Product Brand: Indian

Product Currency: ₹

Product Price: 1450000

Price Valid Until: 2022-11-01

Product In-Stock: PreOrder

5

There are no reviews yet.