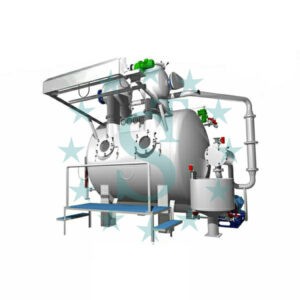

Denim Finishing Range

Denim Finishing Range

The Denim Finishing Range Exclusive purpose is to ensure that the garment made from such fabric does not shrink after the wash hence perfect dimensional stability.

As per standard, + / -1 % residual shrinkage is acceptable. Denim Finishing Range is available for up to 3600mm working width fabric to assure total shrinkage protection to Denim fabrics.

Denim Finishing Range was developed in a way that can shrinkage up to 14% in a single passage.

Denim Finishing Range is usually the last process in the sequence of fabric finishing. The Denim fabric processed in Denim Finishing Range gets fully shrunk.

Before Denim Finishing Range, it is advisable to establish the width at which the cloth should get shrunk in length to meet the requirement of the garment makers. It is the best Fabric Finishing machinery.

🔸 Key Features:

✅ Ensuring Required Shrinkage of 14 Ounce Denim in Single RUN At a Speed of 40 to 50 Mtrs / Min.

✅ Matching all parameters of Shrinkage, Feel, Warp & Weft Tension.

✅ Complete Machine with P.L.C. Controlled Inverter Drive.

✅ Large Touch Screen, Showing Shrinkage, Speed and Other Data, Minimum Usage, of Steam & Power.

✅ User-friendly machine with the shortest Payback time.

✅ Can finish lycra fabrics in a single run with required weft and warp shrinkage at the speed of 40 mt / min.

✅ Specially designed heavy warp pull to control the width of the fabric and warp stretch control by P L C.

✅ Motorized antiskew device to control the skew setting of fabric twill by forwarding and reversing the movement of motors.

✅ Specially developed a shrinking unit to achieve shrinkage up to 14 % depending upon the quality of the fabric with residual shrinkage of 1 %.

✅ 2500mm dia Mirror polished Jacketed main palmer cylinder with rotary joints.

✅ The number of 2 cooling cylinders is provided at the exit of the palmer unit to cool down the fabrics.

⭕ Singing unit at the feeding side. (Optional)

⭕ Brushing unit at feeding side. (Optional)

⭕ Temperature controlling of shrinkage and palmer unit by PLC. (Optional)

⭕ Big Batching device with ‘J’ scray at plating side. (Optional)

₹17,500,000.00

CompareDenim Finishing Range

The Denim Finishing Range Exclusive purpose is to ensure that the garment made from such fabric does not shrink after the wash hence perfect dimensional stability.

As per standard, + / -1 % residual shrinkage is acceptable. Denim Finishing Range is available up to 3600mm working width fabric to assure total shrinkage protection to Denim fabrics.

Denim Finishing Range developed in a way that can shrinkage up to 14% in a single passage.

Denim Finishing Range is usually the last process in the sequence of fabric finishing. The Denim fabric processed in the machine gets fully shrunk.

Before Denim Finishing Range, it is advisable to establish the width at which the cloth should get shrunk in length to meet the requirement of the garment makers. It is the best Fabric Finishing machinery.

🔸 Key Features:

✅ Ensuring Required Shrinkage of 14 Ounce Denim in Single RUN At a Speed of 40 to 50 Mtrs / Min.

✅ Matching all parameters of Shrinkage, Feel, Warp & Weft Tension.

✅ Complete Machine with P.L.C. Controlled Inverter Drive.

✅ Large Touch Screen, Showing Shrinkage, Speed and Other Data, Minimum Usage, of Steam & Power.

✅ User-friendly machine with the shortest Payback time.

✅ Can finish lycra fabrics in a single run with required weft and warp shrinkage at the speed of 40 mt / min.

✅ Specially designed heavy warp pull to control the width of the fabric and warp stretch control by P L C.

✅ Motorized antiskew device to control the skew setting of fabric twill by forwarding and reversing the movement of motors.

✅ Specially developed a shrinking unit to achieve shrinkage up to 14 % depending upon the quality of the fabric with residual shrinkage of 1 %.

✅ 2500mm dia Mirror polished Jacketed main palmer cylinder with rotary joints.

✅ Numbers of 2 cooling cylinders are provided at the exit of the palmer unit to cool down the fabrics.

⭕ Singing unit at the feeding side. (Optional)

⭕ Brushing unit at feeding side. (Optional)

⭕ Temperature controlling of shrinkage and palmer unit by PLC. (Optional)

⭕ Big Batching device with ‘J’ scray at plating side. (Optional)

🔸 Payment, Taxes and Delivery

Payment: Before dispatch of machinery, 40% advance and a balance against the proforma invoice.

Delivery: Delivery of machine ideally comes within 4 to 6 weeks.

Freight: Will be paid by the customer.

Sales Tax: GST 18% (Domestic Orders) Or Vat 4% +1% No CST against form “H”( export orders).

Installation: Will be charged extra per machine over and above the price.

1. Select Product

Choose the required specification & submit the details.

2. Get Offer

Get a Detailed Offer.

3. Pay The Advance

Pay the advance amount as per agreed terms.

4. Product Under Construction

Product goes under Construction according agreed time.

5. Pay The Rest Amount

Pay the balance amount as your machine get ready to dispatch.

6. Shipment Initiated

Shipment option available through Manufacturer.

7. Installation

Finally, the product will be installed at your plant.

| Type | WET FINISHING, FORM FINISHING |

|---|---|

| Roller Width | 1600, 1800, 2000, 2200, 2400, 2600, 2800, 3000, 3200, 3400, 3600 |

Based on 0 reviews

Be the first to review “Denim Finishing Range”

-

Burner, Heating Solution

Burner 200 – Stage 2

Burner 200 | Heating solution

The Gas Burner 200 is a heating solution for small-medium appliances. The gas burner can be used as either a primary or secondary heating source, offering great versatility to users. It is designed not only to be functional but also beautiful.

We designed this, will ensure you have a high-efficiency, energy-efficient heating solution.

The gas burner was created as a way of providing an aesthetically pleasing solution for companies looking for a simpler alternative.

Benefits

✅ Modern design

✅ Efficient

✅ Aesthetic

✅ Environmentally friendly

✅ Reduces air pollution because it reduces wood consumption by up to 5 times

✅ Tangential Ventilation

✅ Heats quickly and efficiently

SKU: n/a -

Dyeing Machinery

Semi Automatic Jigger Machine

Semi Automatic Dyeing Jigger

Roll Center 31″ (790 mm) – 36″ (915mm)

Capacity 350-500 Kg. (250 gsm)

Batch Dia 900-1100 mm

Available Width : 48″ To 150″ Roller WidthSemi Automatic Jumbo Jigger Machine

Roll Center 31″ (790 mm) – 36″ (915mm)

Capacity 350-500 Kg. (250 gsm)

Batch Dia 900-1100 mm

Available Width : 48″ To 150″ Roller Width[spbsm-follow-buttons]

SKU: n/a -

Dyeing Machinery

HT.HP. Soft Over Flow

HTHP Soft Over Flow is just like the HTHP Soft Flow machine with a bigger capacity & for heavy fabrics.

HTHP Soft Over Flow is Specially Designed to process Heavy and sensitive fabrics like Terry Towel, and Curtain Bedsheet of 100% Cotton knit and woven fabrics. In short, it’s a Terry towel dyeing machine.

HTHP Soft Over Flow can work as a Soft Overflow with minor adjustments.

A larger nozzle diameter, with a Higher volume & low-pressure nozzle design and inside Teflon sheet are helpful to move the fabric very smoothly and gently without damaging the cloth.

A specially develop online filter design helps to collect the Terry towel fumes.

🔸 Technical Specification

✅ Capacity: 50 to 2000 kg.

✅ The process has a sensitive fabric like Terry Towels, Curtain, Bed Sheet, 100% cotton knit & woven etc.

✅ Work as Soft flow or as overflow dyeing.

✅ High Temp. – Up to 140 ° C.

✅ The vessel makes of stainless steel 316 L.

✅ Specially developed a filter to collect towel fumes.

✅ Teflon Sheet inside the chamber for smooth fabric movement.

✅ High volume, Low-pressure soft nozzle with a larger diameter for heavy and Larger width fabrics

✅ Fabric drive reel with frequency controller.

SKU: D/HSO-1 -

Accessories

A Frame

A-FRAME Trolley

A-Frame trolley is one of the most required Accessories in Textile Plant and Mills. A-frame’s objective is to carry the fabric and make it easy to manoeuvre inside the facility while different processes such as measuring, washing, cleaning, dyeing or printing, and finishing.

A-frame trolleys are also Utilised in rotating stations by simply adding an extension to them.

A-frame trolleys come in different sizes from 44 to 130 inches roller width depending on the customer. A-frame trolleys take less space than bucket/box-type trolleys. It gets easier to manage them and store them in one place.

Inshot A-Frame Tolleys are best to manage and store the grey to finished material in a clean and sorted way that helps to identify the fabric lot.

Many Textile mills and Export houses have been using it for a long time, making it reliable and one of the solutions to manage the fabric.

🔸 Technical Specification

✅ A FRAME’s top roll fabricate from M.S. Seamless Pipe (Ebonite quoting).

✅ The end shaft is RIB constructed or As per the buyer’s suggestion.

⭕ Cladding of S.S. Sheet on a batch roll. (Optional)

✅ The front side pooling system is a swivel-type M.S. fabricated bracket with 10″ x 2 wheels.

✅ The rare side is of fixed type 12″ x 3″ wheel.

✅ Batch coupling is fit on a batch roll for rotating.

✅ A-FRAME is manufactured from an M.S. channel (100/50mm) x 6mm wall thickness.

SKU: A/T-1 -

Dyeing Machinery

Hydraulic Jigger

Hydraulic Jigger

Hydraulic Jigger is a piece of revolutionary equipment for open-width Scouring, Bleaching & Dyeing processes in batch form. One of the best Dyeing machinery with perfect dyeing results. Hydraulic Jigger has the following features:

- Firstly, Hydraulic Jigger’s Adjustable tension according to Fabric quality ensures perfect pre-treatment and dyeing irrespective of run lengths for the same shade/colour. In other words, Hydraulic Jigger dyes the Clothing rapidly with accuracy.

- Secondly, Hydraulic Jigger comes with closed chambers with doors that close while the operation is performing. Which gives it desired temperature in less time. Therefore, less wastage of resources.

- Thirdly, Consistent dyeing of the same shade for any number of times in the future, Moreover the highly efficient washing system saves washing time and precious Water. The uniform tension, process time, and ideal temperature contribute to the dying quality.

- Fourthly, Hydraulic Jigger controls these parameters resulting in fully controllable and reproducible shades. The controlled temperature and a steady circulation of dye liquid for flawless dyeing. PLC aided operation for repeatability. Suiting, shirting, and delicate fabrics such as rayon are best suited.

- Fifthly, the Hydraulic Jigger is available in 500kg and 1000kg capacity from 1200mm to 3000mm working width depending on the client’s need. Fabric ranging from 70 to 700 gsm/meter square of woven material may be dyed in a Hydraulic Jigger, making it ideal for Suiting, Shirting, and Delicate textile such as rayon.

Above all, flawless synchronisation of linear speed results in tension-free and crease-free fabric conveyance throughout the process.

🔸 Technical Specification

➡ Automatic reversal at the end of each cycle setting

➡ Spray washing through a selector switch

➡ Stopping the machine at the pre-determined sampling point

➡ Water filling through rotary switch

➡ Drain through a selector switch

➡ Digital Speed indication

➡ Speed setting through P L C

➡ Replenishing from dosing tank through valve

➡ Indirect steam heating through Heat Exchanger

➡ Temperature Controller.

➡ A valve adjusts the tension on the cloth.

➡ Soft Start & Stop

➡ Pendulation when adding and emptying liquid

➡ Touch Screen

➡ Specially designed software for the machine

SKU: n/a -

Dyeing Machinery

Jigger

Fabric dyeing machines can come in all shapes and sizes, but

A Jigger is typically an open-framed machine with a rotating drum that holds the fabric to be dyed. Jigger is the standard and oldest way to dye cotton and cotton blend fabric.

The jigger machine has been used for a long time to treat small to medium size lots of woven fabric with an open-width exhaust dyeing process. Dye jiggers are available in Two variants 1st Jigger is an Open type with the following options:

✅ Fully S.S. construction or Mounted on C.I. Walls.

✅ With a water re-circulation system and temperature controllers.

✅ A.C. Motor drive or Inverter Control Drive

✅ Semi Automatic or Fully Automatic

✅ S.S. Cladded Batch Rollers of Ebonite coated Batch Rollers2nd one is a Close type with the following advancement:

✅ Gear Box Type Semi Automatic Maxi Jigger Machine

✅ S.S. Spring Type Floating Device

✅ Roof Heating is Provided to Prevent Dropping on Fabrics

✅ Direct & Indirect Heating with Temperature Controller

✅ Auto R/F System with Cycle Contrail with the help of PLC

⭕ Pneumatic Operated Auto Drain (Optional)

⭕ A Direct Mounted Reduction Gear Box (Optional)🔸 Technical Specification

✅ The Machines are available from 1250mm to 3400mm in width

✅ Roll Center: 25″, 31″, 36″, 41″

✅ Complete Stainless Steel Body with M.S. Base Frame

✅ Capacity: 225 Kg., 350 Kg., 500 Kg., 750Kg., 1000Kg., 1500Kg.(250 Gsm)

✅ Complete Stainless Steel Body.

✅ Heavy-duty brake drum.

✅ Heavy duty differential Gear unit.

✅ A.C. Frequency Drive.

✅ Stainless Steel Cladded Main Roll

✅ Circulation System with 2.0 H.P.In conclusion, This is best for small batches to mass dyeing lots with the durable built of Stainless Steel it gives durability instead of the lower model. The water re-circulation system makes accurate dyeing results while keeping the fabric clean. Heavy-duty brake drums give precise tension to the cloth with the help of an A.C. Frequency drive.

In short, It is the basic necessity for a small dyeing house to a large dyeing industry with less space and higher capacity. It is the Best Fabric Dyeing machine for small to medium size cotton dyeing units.

SKU: jigger

There are no reviews yet.