A Frame

A-FRAME Trolley

A-Frame trolley is one of the most required Accessories in Textile Plant and Mills. A-frame’s objective is to carry the fabric and make it easy to manoeuvre inside the facility while different processes such as measuring, washing, cleaning, dyeing or printing, and finishing.

A-frame trolleys are also Utilised in rotating stations by simply adding an extension to them.

A-frame trolleys come in different sizes from 44 to 130 inches roller width depending on the customer. A-frame trolleys take less space than bucket/box-type trolleys. It gets easier to manage them and store them in one place.

Inshot A-Frame Tolleys are best to manage and store the grey to finished material in a clean and sorted way that helps to identify the fabric lot.

Many Textile mills and Export houses have been using it for a long time, making it reliable and one of the solutions to manage the fabric.

🔸 Technical Specification

✅ A FRAME’s top roll fabricate from M.S. Seamless Pipe (Ebonite quoting).

✅ The end shaft is RIB constructed or As per the buyer’s suggestion.

⭕ Cladding of S.S. Sheet on a batch roll. (Optional)

✅ The front side pooling system is a swivel-type M.S. fabricated bracket with 10″ x 2 wheels.

✅ The rare side is of fixed type 12″ x 3″ wheel.

✅ Batch coupling is fit on a batch roll for rotating.

✅ A-FRAME is manufactured from an M.S. channel (100/50mm) x 6mm wall thickness.

₹35,000.00

CompareA-FRAME Trolley

A-Frame trolley is one of the most required Accessories in Textile Plant and Mills. A-frame’s objective is to carry the fabric and make it easy to manoeuvre inside the facility while different processes such as measuring, washing, cleaning, dyeing or printing, and finishing.

These trolleys are also Utilised in rotating stations by simply adding an extension to them.

These trolleys come in different sizes from 44 up to 130 inches roller width depending on the customer. trolleys take less space than bucket/box type trolleys. It gets easier to manage them and store them in one place.

🔸 Technical Specification

✅ A FRAME’s top roll fabricate from M.S. Seamless Pipe (Ebonite quoting).

✅ The end shaft is RIB constructed or As per the buyer’s suggestion.

⭕ Cladding of S.S. Sheet on a batch roll. (Optional)

✅ The front side pooling system is a swivel type M.S. fabricated bracket with 10″ x 2 wheels.

✅ The rare side is of fixed type 12″ x 3″ wheel.

✅ Batch coupling is fit on a batch roll for rotating.

✅ A-FRAME is manufactured from an M.S. channel (100/50mm) x 6mm wall thickness.

🔸 Payment, Taxes and Delivery

Payment: Before dispatch of machinery, 40% advance and a balance against the proforma invoice.

Delivery: Delivery of machine ideally comes within 4 to 6 weeks.

Freight: Will be paid by the customer.

Sales Tax: GST 18% (Domestic Orders) Or Vat 4% +1% No CST against form “H”( export orders).

Installation: Will be charged extra per machine over and above the price.

1. Select Product

Choose the required specification & submit the details.

2. Get Offer

Get a Detailed Offer.

3. Pay The Advance

Pay the advance amount as per agreed terms.

4. Product Under Construction

Product goes under Construction according agreed time.

5. Pay The Rest Amount

Pay the balance amount as your machine get ready to dispatch.

6. Shipment Initiated

Shipment option available through Manufacturer.

7. Installation

Finally, the product will be installed at your plant.

A-Frame | Accessories | 44" to 130" Roller | Best for Mills

A-frame trolly is one of the most required Accessories in Textile Plant and Mills. A-frame's objective is to carry the fabric and make it easy to manoeuvre.

Product SKU: A/T-1

Product Brand: Indian

Product Currency: ₹

Product Price: 35000

Price Valid Until: 2023-08-01

Product In-Stock: PreOrder

4

| Roller Width | 1400 mm, 1500 mm, 1600 mm, 1700 mm, 1800 mm, 1900 mm, 2000 mm, 2100 mm, 2200 mm, 2300 mm, 2400 mm, 2500 mm, 2600 mm, 2700 mm, 2800 mm, 2900 mm, 3000 mm, 3100 mm, 3200 mm |

|---|

A-Frame | Accessories | 44" to 130" Roller | Best for Mills

A-frame trolly is one of the most required Accessories in Textile Plant and Mills. A-frame's objective is to carry the fabric and make it easy to manoeuvre.

Product SKU: A/T-1

Product Brand: Indian

Product Currency: ₹

Product Price: 35000

Price Valid Until: 2023-08-01

Product In-Stock: PreOrder

4

Youtube

A-Frame | Accessories | 44" to 130" Roller | Best for Mills

A-frame trolly is one of the most required Accessories in Textile Plant and Mills. A-frame's objective is to carry the fabric and make it easy to manoeuvre.

Product SKU: A/T-1

Product Brand: Indian

Product Currency: ₹

Product Price: 35000

Price Valid Until: 2023-08-01

Product In-Stock: PreOrder

4

Based on 0 reviews

Be the first to review “A Frame”

-

Batching, Makeup Machinery

Fabric Rolling

The prime objective of fabric rolling is to roll fabric on paper tube or PVC pipe from loose/fold form which makes easy to store fabric in an organised way. Meanwhile, recognising fabric before shipping it.

- Firstly, Rolls can be made from 100mm to 1000mm depending on need.

- Secondly, Machine working width can be made from 1000mm to 3500mm depending on client’s need.

- Thirdly, Fabric ranging from 70 gsm/meter square up to 700 gsm/meter square of woven fabrics like cotton, viscose, rayon, wool & polyester can be roll on this machine.

- Forth and most importantly the speed can be achieve up to 40 meters per minute while preforming the process.

In conclusion, this machine is best suitable for garment industry or fabric warehouse.

[spbsm-follow-buttons]

SKU: n/a -

Accessories

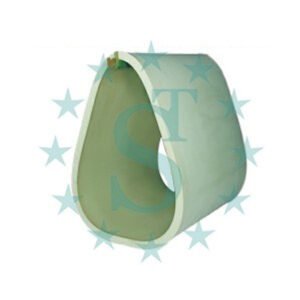

Rubber Blanket

Rubber Blanket

in the textile finishing process for pre-shrinking fine, lightweight cloth, Twills, Drills, & other medium-weight fabrics. Rubber Blanket has the following features:

- Firstly, the Rubber Blanket is produced from the highest quality, dirt-free natural rubber and selective quality polymers to give extremely high compressive strength to the product.

- Secondly, it ensures a non-stick surface for excellent fabric finish during the shrinkage process of textile.

- Thirdly, the high-quality speciality rubber additive with high-performance anti-degradants is selected to prevent surface degradation of the Rubber Blanket at high-temperature processing, which gives excellent heat resistance and superior flex life to the product.

- Fourthly, a Superior quality Rubber blanket can effortlessly process at high steam pressure on modern high-speed machines to give shrinkage-free fabrics. Because of the heat resistance nature of the Rubber Blanket, it Gives uninterrupted service before stopping the machine from grinding the new smooth surface.

- Fifthly, The good abrasive surface and excellent flex quality of the Rubber Blanket are Expected to give at least 10 to 15% higher meterage of fabric under ideal processing conditions than other brands of Rubber Banket available in the Indian market.

Moreover, Producers of lightweight, low shrinkage potential, 100% cotton or cotton/polyester, commonly report from 15 million to 20 million meters of productive life.

🔶 Technical Specification

- Hardness: The recommended hardness of a Rubber Blanket is between 36 degrees to 39 degrees depending on the fabrics to be processed.

- Fabric Width: offer current width of 1200mm to 3500mm.

- Usually, Rubber Banket should be 150 mm to 200 mm wider than FELT the cloth to be processed.

- Pressure Circumference: The standard internal circumference of the Rubber Blanket is 3962mm (13 feet)

- Thickness: The most common thickness of a Rubber Blanket is 67 mm (2.5/8″) and varies up to 70mm. The higher thickness will initially require higher force for outer surface elongation as the Blanket turns around the pressure. Results in cracks on the outer surface & will need to grind the surface frequently and often rubbing the Rubber Blanket from the inner surface. Usually, Rubber Blanket thickness depends on the required shrinkage in fabrics.

- The Rubber Blanket has a maximum shrinkage capacity of Up to 15% for lightweight fabric processed on a comfit type machine 50 mm.

- Usually, Rubber Belt thickness depends on the shrinkage needed in fabrics. For lightweight processed fabrics with low shrinkage fabrics such as poplins, fancy prints & synthetics dress material etc., a Belt thickness of 55 mm is required. This rubber belt will have a shrinkage capacity of 5-8% for processing heavy weight fabrics like Denim, Twill, Drills etc. thickness Belt of 67-71 mm is needed. The Rubber Belt has a maximum shrinkage capacity of Up to 15% for lightweight fabrics processed on a comfit type machine 50 mm A thick belt is most suitable with 3-5% shrinkage.

In conclusion, Rubber Blanket is best suitable for the garment industry or dyeing & printing plants which use the machines like Compressive Shrinking Range or Zero Zero & Comfit.

SKU: n/a -

Processing Machinery

Desizing Machine

Desizing machine

Desizing is the process of removing the size applied during weaving. The purpose of this fabric processing machinery Desizing machine is to remove the sizing ingredients such as starches, gums, PVA etc.

The starch has to be degraded into less water-soluble molecules by hydrolysis. The hydrolysis of starch using enzymes under particular concentration, temperature and duration is called desizing.

Desizing can do at room temperature to boiling temperature as per the quality of the enzyme.

Desizing Tank is made from Stainless Steel material. The tank can have open or fully enclosed construction as per requirement. The number of rollers in the tank facilitates suitable liquor takeup of every kind of fabric which is to be desized.

Desizing machine speed can be lowered or raised for proper take-up of the liquor for different grades of cloth.

🔸 Key Functions:

✅ 5 to 60Mtrs/Min operational speed.

⭕ Automatic or manual dozing system (Optional)

✅ Auto Steam Control.

✅ Easy usage.

⭕ Chemical preparation tanks (Optional)

✅ Desizing machines are available from 1600mm to 3400mm fabric width.

SKU: P/DM-1 -

Dyeing Machinery

Hydraulic Jigger

Hydraulic Jigger

Hydraulic Jigger is a piece of revolutionary equipment for open-width Scouring, Bleaching & Dyeing processes in batch form. One of the best Dyeing machinery with perfect dyeing results. Hydraulic Jigger has the following features:

- Firstly, Hydraulic Jigger’s Adjustable tension according to Fabric quality ensures perfect pre-treatment and dyeing irrespective of run lengths for the same shade/colour. In other words, Hydraulic Jigger dyes the Clothing rapidly with accuracy.

- Secondly, Hydraulic Jigger comes with closed chambers with doors that close while the operation is performing. Which gives it desired temperature in less time. Therefore, less wastage of resources.

- Thirdly, Consistent dyeing of the same shade for any number of times in the future, Moreover the highly efficient washing system saves washing time and precious Water. The uniform tension, process time, and ideal temperature contribute to the dying quality.

- Fourthly, Hydraulic Jigger controls these parameters resulting in fully controllable and reproducible shades. The controlled temperature and a steady circulation of dye liquid for flawless dyeing. PLC aided operation for repeatability. Suiting, shirting, and delicate fabrics such as rayon are best suited.

- Fifthly, the Hydraulic Jigger is available in 500kg and 1000kg capacity from 1200mm to 3000mm working width depending on the client’s need. Fabric ranging from 70 to 700 gsm/meter square of woven material may be dyed in a Hydraulic Jigger, making it ideal for Suiting, Shirting, and Delicate textile such as rayon.

Above all, flawless synchronisation of linear speed results in tension-free and crease-free fabric conveyance throughout the process.

🔸 Technical Specification

➡ Automatic reversal at the end of each cycle setting

➡ Spray washing through a selector switch

➡ Stopping the machine at the pre-determined sampling point

➡ Water filling through rotary switch

➡ Drain through a selector switch

➡ Digital Speed indication

➡ Speed setting through P L C

➡ Replenishing from dosing tank through valve

➡ Indirect steam heating through Heat Exchanger

➡ Temperature Controller.

➡ A valve adjusts the tension on the cloth.

➡ Soft Start & Stop

➡ Pendulation when adding and emptying liquid

➡ Touch Screen

➡ Specially designed software for the machine

SKU: n/a -

Dyeing Machinery

HT.HP. Soft flow

HTHP Soft flow

- First and foremost, HTHP Soft Flow Dyeing Machine is suitable for sensitive surface structures and natural fabrics. All fabrics like cotton, wool, viscose, acrylic and blends of jersey, terry towel, velour and nylon.

- Secondly, HTHP Soft Flow Machine is a contemporary technology that uses a curved nozzle to transfer the cloth smoothly at a high fluid flow. As a result, reduce strain and avoid creases and peeling.

- Thirdly, by the new design, HTHP Soft Flow takes the Lowest liquor ratio up to 1:5 (on wet material) instead of the conventional design taking the liquor ratio up to 1:10 (on wet).

- Fourthly, HTHP Soft Flow is made of high-quality steel inside and out, making it rust-resistant.

- Fifthly, the nozzles inside HTHP Soft Flow come with 316L Quality stainless steel. It gives smooth operation to the cloth.

- Lastly, HTHP Soft Flow includes numerous safety features.

In conclusion, it is perfect for modern textile dyeing plants.

🔸 Technical Specification

✅ Lowest liquor ratio up to 1:5 (wet Fabric)

✅ Capacity: 50 to 2000 kg.

✅ Dye –30 To 500 Grms/Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

✅ High Temp. – Up to 140° C.

✅ The vessel builds from stainless steel SS 316L Quality.➡ Online filter for easy clean-up even during the process with an extra filter mesh.

➡ For smooth fabric circulation, a Teflon Sheet is inside the chamber.

➡ Cup type very soft nozzle with low pressure & higher volume design.

➡ The fabric driving reel comes with a frequency controller.

SKU: D/HSF-1

There are no reviews yet.