Compressive Shrinking Range

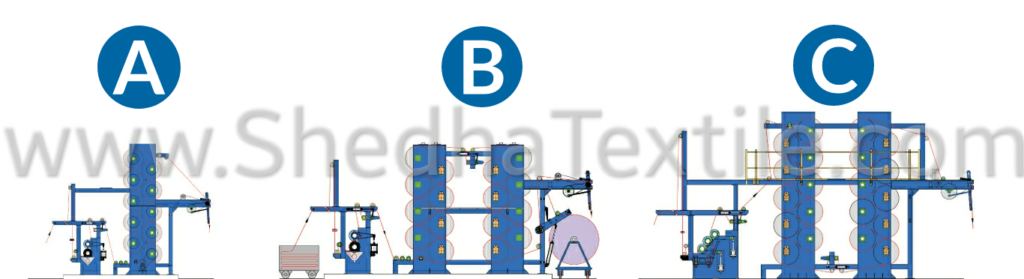

The Sole purpose of the Controlled Compressive Shrinking Range or ZEROZERO is to ensure that the garment made from such fabric does not shrink after the wash hence perfect dimensional stability.

As per standard, + / -1 % residual shrinkage is acceptable. Controlled Compressive Shrinking Range or ZEROZERO are available up to 3200mm working width fabric to assure total shrinkage protection to woven fabrics. It can be 100% cotton, cotton/polyester, cotton/viscose or tough and heaviest fabric like denim. Compressive Shrinking Range or ZEROZERO developed in a way that can shrinkage up to 12% in a single passage.

The most capable of shrinking medium, lightweight fabric to the heaviest denim, cotton blended suiting & shirting by watering cotton, terylene, hemp and its blends to shrink the cloth to meet the requirements of shrinkage, stabilization and improve the hand touch.

A controlled Compressive Shrinking Range is usually the last process in the sequence of fabric finishing. The woven fabric processed in the machine gets fully shrunk.

Before compressive shrinking, it is advisable to establish the width at which the cloth should get shrunk in length to meet the requirement of the garment makers. It is the best Fabric Finishing machinery.

🔸 Technical Specification

✅ A.C. frequency conversion transmission, designed speed: 10-80m/minute.

✅ Shrinkage 0 – 12 % depending upon fabric quality.

✅ Minimum and controlled tension.

⭕ Imported Rubber Blanket and Polyester Felt will be provided optionally.

✅ A Jacketed drum in 1500mm, 2000mm and 2500mm diameters.

✅ Stainless Steel damping & conditioning unit supplied as standard Parts.

₹2,500,000.00

CompareCompressive Shrinking Range

The Sole purpose of Controlled Compressive Shrinking Range or ZEROZERO is to ensure that the garment made from such fabric does not shrink after the wash hence perfect dimensional stability.

As per standard, + / -1 % residual shrinkage is acceptable. Controlled Compressive Shrinking Range or ZEROZERO are available up to 3200mm working width fabric to assure total shrinkage protection to woven fabrics. It can be 100% cotton, cotton/polyester, cotton/viscose or tough and heaviest fabric like denim. Compressive Shrinking Range or ZEROZERO developed in a way that can shrinkage up to 12% in a single passage.

The most capable of the shrinking medium, lightweight fabric to the heaviest denim, cotton blended suiting & shirting by watering cotton, terylene, hemp and its blends to shrink the cloth to meet the requirements of shrinkage, stabilization and improve the hand touch.

A controlled Compressive Shrinking Range is usually the last process in the sequence of fabric finishing. The woven fabric processed in the machine gets fully shrunk.

Before compressive shrinking, it is advisable to establish the width at which the cloth should get shrunk in length to meet the requirement of the garment makers.

🔸 Technical Specification

✅ A.C. frequency conversion transmission, designed speed: 10-80m/minute.

✅ Shrinkage 0 – 12 % depending upon fabric quality.

✅ Minimum and controlled tension.

⭕ Imported Rubber Blanket and Polyester Felt will be provided optionally.

✅ A Jacketed drum in 1500mm, 2000mm and 2500mm diameters.

✅ Stainless Steel damping & conditioning unit supplied as standard Parts.

🔸 Payment, Taxes and Delivery

Payment: Before dispatch of machinery, 40% advance and a balance against the proforma invoice.

Delivery: Delivery of machine ideally comes within 4 to 6 weeks.

Freight: Will be paid by the customer.

Sales Tax: GST 18% (Domestic Orders) Or Vat 4% +1% No CST against form “H”( export orders).

Installation: Will be charged extra per machine over and above the price.

1. Select Product

Choose the required specification & submit the details.

2. Get Offer

Get a Detailed Offer.

3. Pay The Advance

Pay the advance amount as per agreed terms.

4. Product Under Construction

Product goes under Construction according agreed time.

5. Pay The Rest Amount

Pay the balance amount as your machine get ready to dispatch.

6. Shipment Initiated

Shipment option available through Manufacturer.

7. Installation

Finally, the product will be installed at your plant.

Controlled Compressive Shrinking Range | Fabric finishing | best shrinkage up to 12%

Controlled Compressive Shrinking Range is to ensure that the garment made from such fabric does not shrink after wash hence perfect dimensional stability.

Product SKU: F/CSR-1

Product Brand: Indian

Product Currency: ₹

Product Price: 2500000

Price Valid Until: 2023-08-01

Product In-Stock: PreOrder

5

| Machine width | 1600mm, 1800mm, 2000mm, 2200mm, 2400mm, 2600mm, 2800mm, 3000mm, 3200mm |

|---|---|

| Jacketed drum Dia | 1500mm, 2000mm, 2500mm |

Controlled Compressive Shrinking Range | Fabric finishing | best shrinkage up to 12%

Controlled Compressive Shrinking Range is to ensure that the garment made from such fabric does not shrink after wash hence perfect dimensional stability.

Product SKU: F/CSR-1

Product Brand: Indian

Product Currency: ₹

Product Price: 2500000

Price Valid Until: 2023-08-01

Product In-Stock: PreOrder

5

Based on 0 reviews

Be the first to review “Compressive Shrinking Range”

-

Processing Machinery

Desizing Machine

Desizing machine

Desizing is the process of removing the size applied during weaving. The purpose of this fabric processing machinery Desizing machine is to remove the sizing ingredients such as starches, gums, PVA etc.

The starch has to be degraded into less water-soluble molecules by hydrolysis. The hydrolysis of starch using enzymes under particular concentration, temperature and duration is called desizing.

Desizing can do at room temperature to boiling temperature as per the quality of the enzyme.

Desizing Tank is made from Stainless Steel material. The tank can have open or fully enclosed construction as per requirement. The number of rollers in the tank facilitates suitable liquor takeup of every kind of fabric which is to be desized.

Desizing machine speed can be lowered or raised for proper take-up of the liquor for different grades of cloth.

🔸 Key Functions:

✅ 5 to 60Mtrs/Min operational speed.

⭕ Automatic or manual dozing system (Optional)

✅ Auto Steam Control.

✅ Easy usage.

⭕ Chemical preparation tanks (Optional)

✅ Desizing machines are available from 1600mm to 3400mm fabric width.

SKU: P/DM-1 -

Batching, Makeup Machinery

Single Folding Machine

This Single Folding machine or fabric folding machine is one of the fabric makeup machinery which has the following features :

- Firstly, the Single Folding machine does fold the fabric from a loose form to an organized plated state before performing dyeing/printing/processing operations.

- In other words, the fabric needs an inspection before starting any processes.

- Secondly, the Single Folding machine also measures fabric length before any operation or after all processes.

- Thirdly, the Single Folding machine comes in four different sizes from 41″/36 (Small)* to 72″/67 (Large)

- Fourthly, woven fabrics like cotton, viscose, rayon, wool & polyester weigh from 70 to 700 gsm/meter square and fold on a Single Folding machine.

- Fifth and most importantly, the speed can be achieved up to 50 meters per minute while performing the process.

In conclusion, this fabric folding machine is best suitable for the garment industry or dyeing & printing plants.

🔸 Technical Specification

✅ For fabric up to 1700MM

✅ The working table descends up to 15” (380 mm).

✅ Length is of folds adjustable up to 1.00 meter.

✅ Cast Iron sidewalls are closed to make the machine robust and sturdy.

✅ Folding blades mounted on the carriage of steel roller chains.

✅ a simple device for quick and precise folding with knife adjustment

✅ Operating speed: 50 meters/minute.

✅ Drive on motor 2HP x 960RPM.

✅ Stroke-type length Counter with manual setting or ⭕ Digital counter.

SKU: n/a -

Accessories

A Frame

A-FRAME Trolley

A-Frame trolley is one of the most required Accessories in Textile Plant and Mills. A-frame’s objective is to carry the fabric and make it easy to manoeuvre inside the facility while different processes such as measuring, washing, cleaning, dyeing or printing, and finishing.

A-frame trolleys are also Utilised in rotating stations by simply adding an extension to them.

A-frame trolleys come in different sizes from 44 to 130 inches roller width depending on the customer. A-frame trolleys take less space than bucket/box-type trolleys. It gets easier to manage them and store them in one place.

Inshot A-Frame Tolleys are best to manage and store the grey to finished material in a clean and sorted way that helps to identify the fabric lot.

Many Textile mills and Export houses have been using it for a long time, making it reliable and one of the solutions to manage the fabric.

🔸 Technical Specification

✅ A FRAME’s top roll fabricate from M.S. Seamless Pipe (Ebonite quoting).

✅ The end shaft is RIB constructed or As per the buyer’s suggestion.

⭕ Cladding of S.S. Sheet on a batch roll. (Optional)

✅ The front side pooling system is a swivel-type M.S. fabricated bracket with 10″ x 2 wheels.

✅ The rare side is of fixed type 12″ x 3″ wheel.

✅ Batch coupling is fit on a batch roll for rotating.

✅ A-FRAME is manufactured from an M.S. channel (100/50mm) x 6mm wall thickness.

SKU: A/T-1 -

Dyeing Machinery

Automatic Jigger

Automatic JIGGER is one of the best dyeing machine inventions for simplifying the dying process. Automatic JIGGER is a Hybrid of hydraulic & conventional JIGGER.

Automatic JIGGER comes with two types 1st one is OPEN TYPE & other one is CLOSE TYPE.

Where One-hand OPEN TYPE Automatic JIGGER comes with all the benefits like

✅ Auto tension control

✅ Auto speed control

✅ Auto cycle control

✅ Circulation system with filters to avoid centre to selvedge

✅ Suitable for any exhaust pre-treatment, dyeing & finish process

✅ Tension setting device to avoid running crease & machine jerks

⭕ Auto pendulum control (optional)

⭕ Batching or winch device (optional)

⭕ Auto water level controller (optional)

⭕ Pneumatic operated drain (optional)Otherhand CLOSE TYPE Automatic JIGGER comes with the additional features like

✅ Auto circulation system

✅ Auto temperature controller

✅ A fully covered jigger will save utilities

⭕ Dosing side tank facility (optional)

⭕ Circulation system with filters to avoid centre to narrow border (optional)The tension control system allows Automatic JIGGER to dye any fabric with ease. One operator can run four Automatic JIGGER machines simultaneously thanks to its PLC system, and the individual drive “automatic dyeing jigger” runs on zero tension on the fabric.

Automatic JIGGER uses both rollers powered by separate gearboxes and motors on inverter drives which do wonders for uniform dyes, even when running at varying speeds.

In conclusion, it is the best-woven dyeing machine, fabric dyeing machine or Cotton dyeing machine.

🔶 Technical Specification

✅ Capacity: 300 Kg. to 2000 kg. [OPEN]

✅ Capacity: 500 Kg. to 2000 kg. [CLOSE]

✅ Available Width: 1250mm to 3400mm

✅ S.S. Structure 304 Out Outer body 316 mail rolls plus inner bottom

✅ 0 to 10 Kgs. (Tension less operation Possible)

✅ Suitable for any Fabric from 30gsm to 500gsm

✅ S.S. Cladded Main Roll

✅ Pneumatic cylinders operated doors [CLOSE]

✅ Individual drive on each roller

✅Speed & tension control through a drive

SKU: n/a -

Washing Machinery

Open Width Washing Range

Open width Washing Range

Open width Washing Range is for the fabric washing machine for woven fabrics. The Open width Washing Range machine has the following features.

- Firstly, The system consists of a specially shaped impeller in the drum in which water jets uniformly smashes the full fabric width very high washing performance on the upper and backside of the fabric.

- In other words, Open width Washing Range removes unfixed dyestuff, gum, and other chemicals from the fabric.

- Secondly, Washing with tanks can carry out pre-washing, rinsing, and chemical treatment.

- Therefore, Open width Washing Range improves fabric quality.

- An effective squeezer between the washing unit gives maximum liquor separation from one bath to another.

- Thirdly, Each washing compartment with its force-spray system, re-circulation pump, filtering device, overflow, drain, and heating arrangement.

- Fourthly, the Open width Washing Range’s working width is to be made from 1500mm to 3500mm depending on the client’s need.

- Fifthly, ranging from 70 gsm/meter square up to 700 gsm/meter square of woven fabric can be processed on this machine.

- Sixth and most Important is Perfect synchronizing of linear speed hence tension-less and creaseless transport of fabric all along the process.

🔶 ADVANTAGES :

✅ Excellent Washing efficiency.

✅ Extremely sturdy construction.

✅ Quiet running.

✅ Low energy consumption.

✅ Ease of operation.

✅ Optional knife spray between each strand of fabric with supply from a separate pump.

✅ Circulation and counter flow arrangement to save water.

✅ Low maintenance.

✅ Quick and simple installation.

✅ Tight closing glass windows on the sides to provide easy access.

✅ Direct steam heating by perforated S S Pipes.

✅ S S bottom rolls running in self-aligning bush bearing.

SKU: n/a

There are no reviews yet.