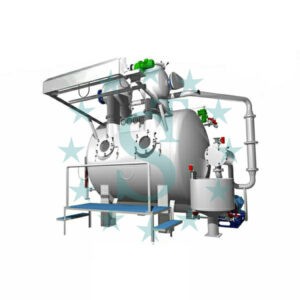

Gas Boiler

GAS Boiler

The Gas Boiler is a packaged three-pass smoke tube with a total wet back boiler. Gas Boiler comes in two three series for burning light oils & gas and heavy oils.

The Gas Boiler also can be customized to a complete skid mount unit on customer demand.

When fitted with a particular burner, these boilers are ideal for burning waste gases like biogas from the decomposition of organic matter in distilleries.

🔸 PRODUCTS FEATURES:

✅ Three-pass smoke tube with complete wet back boiler.

⭕ Multi-fuel option – light oils/heavy oils/gases

✅ High efficiency of about 88% to 95%

✅ High dryness fraction steam increases usable heat.

✅ Gas Boiler Comes with mono-block/ dual block/steam atomized burner with world-renowned Technology from (ITALY)

⭕ An additional option of oil pre-heater confirming EN safety standards

✅Corrugated furnaces for boilers above 6 TPH capacity.

⭕ Optional PLC-based control panels that would be linked to SCADA or DCS systems.

🔸 Operating Range:

➡ Capacities In the range of 1.0 TPH to 15 TPH

➡ Pressure: In the range of 10.54 to 17.54 Kg/cm2 (g)

➡ Firing fuels: LDO, FO, LSHS & Natural Gas

➡ Efficiency: Overall efficiency of 88 % (+/-2%) on NCV

₹5,100,000.00

CompareGAS Boiler

The Gas Boiler is a packaged three-pass smoke tube with a total wet back boiler. Gas Boiler comes in two three series for burning light oils & gas and heavy oils.

The Gas Boiler also can be customized to a complete skid mount unit on customer demand.

When fitted with a particular burner, these boilers are ideal for burning waste gases like biogas from the decomposition of organic matter in distilleries.

🔸 PRODUCTS FEATURES:

✅ Three-pass smoke tube with complete wet back boiler.

⭕ Multi-fuel option – light oils/heavy oils/gases.

✅ High efficiency of about 88% to 95%

✅ High dryness fraction steam increases usable heat.

✅ Gas Boiler Comes with mono-block/ dual block/steam atomized burner with world-renowned Technology from (ITALY)

⭕ Additional option of oil pre-heater confirming EN safety standards.

✅ Corrugated furnaces for boilers above 6 TPH capacity

⭕ Optional PLC-based control panels that would be linked to SCADA or DCS systems.

🔸 Operating Range:

➡ Capacities In the range of 1.0 TPH to 15 TPH

➡ Pressure: In the range of 10.54 to 17.54 Kg/cm2 (g)

➡ Firing fuels: LDO, FO, LSHS & Natural Gas

➡ Efficiency: Overall efficiency of 88 % (+/-2%) on NCV

🔸 Payment, Taxes & Delivery:

Payment: 40% Advance and balance against Proforma Invoice before dispatch.

Delivery: Delivery of the machine ideally comes within 4 to 6 weeks.

Freight: Will be paid by the customer.

Sales Tax: GST 18% (Domestic Orders)

Erection: Will be charged extra per machine over and above the given price.

1. Select Product

Choose the required specification & submit the details.

2. Get Offer

Get a Detailed Offer.

3. Pay The Advance

Pay the advance amount as per agreed terms.

4. Product Under Construction

Product goes under Construction according agreed time.

5. Pay The Rest Amount

Pay the balance amount as your machine get ready to dispatch.

6. Shipment Initiated

Shipment option available through Manufacturer.

7. Installation

Finally, the product will be installed at your plant.

| Capacity (Ton) | 1, 1.5, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15 |

|---|---|

| Fuel Type | Oil, Gas |

Based on 0 reviews

Be the first to review “Gas Boiler”

-

Dyeing Machinery

Jigger

Fabric dyeing machines can come in all shapes and sizes, but

A Jigger is typically an open-framed machine with a rotating drum that holds the fabric to be dyed. Jigger is the standard and oldest way to dye cotton and cotton blend fabric.

The jigger machine has been used for a long time to treat small to medium size lots of woven fabric with an open-width exhaust dyeing process. Dye jiggers are available in Two variants 1st Jigger is an Open type with the following options:

✅ Fully S.S. construction or Mounted on C.I. Walls.

✅ With a water re-circulation system and temperature controllers.

✅ A.C. Motor drive or Inverter Control Drive

✅ Semi Automatic or Fully Automatic

✅ S.S. Cladded Batch Rollers of Ebonite coated Batch Rollers2nd one is a Close type with the following advancement:

✅ Gear Box Type Semi Automatic Maxi Jigger Machine

✅ S.S. Spring Type Floating Device

✅ Roof Heating is Provided to Prevent Dropping on Fabrics

✅ Direct & Indirect Heating with Temperature Controller

✅ Auto R/F System with Cycle Contrail with the help of PLC

⭕ Pneumatic Operated Auto Drain (Optional)

⭕ A Direct Mounted Reduction Gear Box (Optional)🔸 Technical Specification

✅ The Machines are available from 1250mm to 3400mm in width

✅ Roll Center: 25″, 31″, 36″, 41″

✅ Complete Stainless Steel Body with M.S. Base Frame

✅ Capacity: 225 Kg., 350 Kg., 500 Kg., 750Kg., 1000Kg., 1500Kg.(250 Gsm)

✅ Complete Stainless Steel Body.

✅ Heavy-duty brake drum.

✅ Heavy duty differential Gear unit.

✅ A.C. Frequency Drive.

✅ Stainless Steel Cladded Main Roll

✅ Circulation System with 2.0 H.P.In conclusion, This is best for small batches to mass dyeing lots with the durable built of Stainless Steel it gives durability instead of the lower model. The water re-circulation system makes accurate dyeing results while keeping the fabric clean. Heavy-duty brake drums give precise tension to the cloth with the help of an A.C. Frequency drive.

In short, It is the basic necessity for a small dyeing house to a large dyeing industry with less space and higher capacity. It is the Best Fabric Dyeing machine for small to medium size cotton dyeing units.

SKU: jigger -

Burner, Heating Solution

Burner 550 – Stage 3

Burner 550 | Heating solution

This heating solution burner 550 comes to volume, potential, and cost efficiency. The Burner 550 is a series stage 3 covers output ranges under 80mg/kWh. These gas burners were designed with an advanced combusting head which provides consistent combustion even under difficult working conditions.

The placement of the components inside the burner permits easy and precise regulation and maintenance.

Benefits

🔥 Amazingly efficient at burning gas

🔥 Stable flame no matter what kind of weather you’re dealing with

🔥 High efficiency (80mg/kWh)

🔥 Efficient, clean combustion

🔥 Power is increased without complications✅ Easy to maintain

✅ Great energy savings

SKU: n/a -

Dyeing Machinery

HT.HP. Soft flow

HTHP Soft flow

- First and foremost, HTHP Soft Flow Dyeing Machine is suitable for sensitive surface structures and natural fabrics. All fabrics like cotton, wool, viscose, acrylic and blends of jersey, terry towel, velour and nylon.

- Secondly, HTHP Soft Flow Machine is a contemporary technology that uses a curved nozzle to transfer the cloth smoothly at a high fluid flow. As a result, reduce strain and avoid creases and peeling.

- Thirdly, by the new design, HTHP Soft Flow takes the Lowest liquor ratio up to 1:5 (on wet material) instead of the conventional design taking the liquor ratio up to 1:10 (on wet).

- Fourthly, HTHP Soft Flow is made of high-quality steel inside and out, making it rust-resistant.

- Fifthly, the nozzles inside HTHP Soft Flow come with 316L Quality stainless steel. It gives smooth operation to the cloth.

- Lastly, HTHP Soft Flow includes numerous safety features.

In conclusion, it is perfect for modern textile dyeing plants.

🔸 Technical Specification

✅ Lowest liquor ratio up to 1:5 (wet Fabric)

✅ Capacity: 50 to 2000 kg.

✅ Dye –30 To 500 Grms/Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

✅ High Temp. – Up to 140° C.

✅ The vessel builds from stainless steel SS 316L Quality.➡ Online filter for easy clean-up even during the process with an extra filter mesh.

➡ For smooth fabric circulation, a Teflon Sheet is inside the chamber.

➡ Cup type very soft nozzle with low pressure & higher volume design.

➡ The fabric driving reel comes with a frequency controller.

SKU: D/HSF-1 -

Finishing Machinery

Relax dryer

The Relax Dryer is the finishing machine to dry hosiery fabric after the fabric has been washed or processed. This Relax Dryer has the following features in it.

- Firstly, The air movement produces undulations in the cloth & at the same time, it expands the knitted fabric causing dimensional shrinkage and selvedge opening.

- In other words, Relax Dryer expands the fabric width while drying it.

- Secondly, Relax Dryer rolls ladder-proof fabrics based on well-known the principle of air impact drying system.

- Thirdly, the cloth moved through the drying chamber on a conveyor belt that overfed to increase length shrinkage.

- Fourthly, The operating width of the Relax Dryer can range from 1600mm to 4200mm. Depending on the specific needs of the client.

- Fifthly, Relax Dryer can process fabric ranging from 70 to 700 gsm/meter square of hosiery.

- Sixth and most Important, velocity can be achieved up to 60 meters per minute while performing the process.

In conclusion, Relax Dryer is best suitable for Dyeing & Printing units.

🔸 Technical Specification

✅The number of chambers: 2 to 8.

✅Conveyor belt width: 1600mm to 4200mm.

✅ Heating system alternatives: Natural Gas, LPG, Steam or Thermic Oil.

✅ Mechanical belt speed: Step less than 0 to 60m/min.

✅ Maximum working temperature: 220 °C.

✅ Blowers: Special design, highly efficient, diagonal location, two blowers in each chamber.

✅ Fabric feeding: Step-less by multiple points.

✅ Conveyor belt direction control: Electro-pneumatic from both sides.

SKU: RD001 -

Batching, Makeup Machinery

Fabric Rolling

The prime objective of fabric rolling is to roll fabric on paper tube or PVC pipe from loose/fold form which makes easy to store fabric in an organised way. Meanwhile, recognising fabric before shipping it.

- Firstly, Rolls can be made from 100mm to 1000mm depending on need.

- Secondly, Machine working width can be made from 1000mm to 3500mm depending on client’s need.

- Thirdly, Fabric ranging from 70 gsm/meter square up to 700 gsm/meter square of woven fabrics like cotton, viscose, rayon, wool & polyester can be roll on this machine.

- Forth and most importantly the speed can be achieve up to 40 meters per minute while preforming the process.

In conclusion, this machine is best suitable for garment industry or fabric warehouse.

[spbsm-follow-buttons]

SKU: n/a -

Dyeing Machinery

HT.HP. Soft Over Flow

HTHP Soft Over Flow is just like the HTHP Soft Flow machine with a bigger capacity & for heavy fabrics.

HTHP Soft Over Flow is Specially Designed to process Heavy and sensitive fabrics like Terry Towel, and Curtain Bedsheet of 100% Cotton knit and woven fabrics. In short, it’s a Terry towel dyeing machine.

HTHP Soft Over Flow can work as a Soft Overflow with minor adjustments.

A larger nozzle diameter, with a Higher volume & low-pressure nozzle design and inside Teflon sheet are helpful to move the fabric very smoothly and gently without damaging the cloth.

A specially develop online filter design helps to collect the Terry towel fumes.

🔸 Technical Specification

✅ Capacity: 50 to 2000 kg.

✅ The process has a sensitive fabric like Terry Towels, Curtain, Bed Sheet, 100% cotton knit & woven etc.

✅ Work as Soft flow or as overflow dyeing.

✅ High Temp. – Up to 140 ° C.

✅ The vessel makes of stainless steel 316 L.

✅ Specially developed a filter to collect towel fumes.

✅ Teflon Sheet inside the chamber for smooth fabric movement.

✅ High volume, Low-pressure soft nozzle with a larger diameter for heavy and Larger width fabrics

✅ Fabric drive reel with frequency controller.

SKU: D/HSO-1

There are no reviews yet.