Jigger

Fabric dyeing machines can come in all shapes and sizes, but

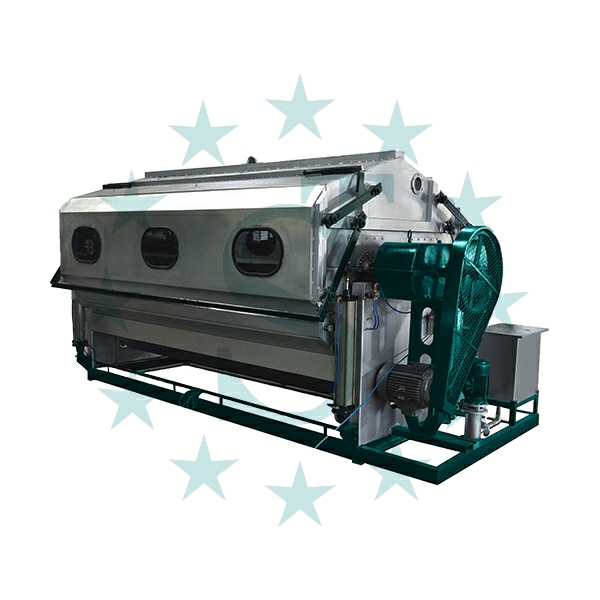

A Jigger is typically an open-framed machine with a rotating drum that holds the fabric to be dyed. Jigger is the standard and oldest way to dye cotton and cotton blend fabric.

The jigger machine has been used for a long time to treat small to medium size lots of woven fabric with an open-width exhaust dyeing process. Dye jiggers are available in Two variants 1st Jigger is an Open type with the following options:

✅ Fully S.S. construction or Mounted on C.I. Walls.

✅ With a water re-circulation system and temperature controllers.

✅ A.C. Motor drive or Inverter Control Drive

✅ Semi Automatic or Fully Automatic

✅ S.S. Cladded Batch Rollers of Ebonite coated Batch Rollers

2nd one is a Close type with the following advancement:

✅ Gear Box Type Semi Automatic Maxi Jigger Machine

✅ S.S. Spring Type Floating Device

✅ Roof Heating is Provided to Prevent Dropping on Fabrics

✅ Direct & Indirect Heating with Temperature Controller

✅ Auto R/F System with Cycle Contrail with the help of PLC

⭕ Pneumatic Operated Auto Drain (Optional)

⭕ A Direct Mounted Reduction Gear Box (Optional)

🔸 Technical Specification

✅ The Machines are available from 1250mm to 3400mm in width

✅ Roll Center: 25″, 31″, 36″, 41″

✅ Complete Stainless Steel Body with M.S. Base Frame

✅ Capacity: 225 Kg., 350 Kg., 500 Kg., 750Kg., 1000Kg., 1500Kg.(250 Gsm)

✅ Complete Stainless Steel Body.

✅ Heavy-duty brake drum.

✅ Heavy duty differential Gear unit.

✅ A.C. Frequency Drive.

✅ Stainless Steel Cladded Main Roll

✅ Circulation System with 2.0 H.P.

In conclusion, This is best for small batches to mass dyeing lots with the durable built of Stainless Steel it gives durability instead of the lower model. The water re-circulation system makes accurate dyeing results while keeping the fabric clean. Heavy-duty brake drums give precise tension to the cloth with the help of an A.C. Frequency drive.

In short, It is the basic necessity for a small dyeing house to a large dyeing industry with less space and higher capacity. It is the Best Fabric Dyeing machine for small to medium size cotton dyeing units.

₹525,000.00

CompareJigger

Fabric dyeing machines can come in all shapes and sizes, but

A Jigger is typically an open-framed machine with a rotating drum that holds the fabric to be dyed. Jigger is a standard and oldest way to dye cotton and cotton blend fabric.

Jigger machine has been used for a long time to treat small to medium size lots of woven fabric with an open-width exhaust dyeing process. Dye jiggers are available in Two variants 1st Jigger is an Open type with the following options:

✅ Fully S.S. construction or Mounted on C.I. Walls.

✅ With a water re-circulation system and temperature controllers.

✅ A.C. Motor drive or Inverter Control Drive

✅ Semi Automatic or Fully Automatic

✅ S.S. Cladded Batch Rollers of Ebonite coated Batch Rollers

2nd Jigger is a Close type with the following advancement:

✅ Gear Box Type Semi Automatic Maxi Jigger Machine

✅ S.S. Spring Type Floating Device

✅ Roof Heating Provided to Prevent Dropping on Fabrics

✅ Direct & Indirect Heating with Temperature Controller

✅ Auto R/F System with Cycle Contrail with the help of PLC

⭕ Pneumatic Operated Auto Drain (Optional)

⭕ The Direct Mounted Reduction Gear Box (Optional)

🔶 Technical Specification

✅ The Machines are available from 1250mm to 3400mm in width

✅ Roll Center: 25″, 31″, 36″, 41″

✅ Complete Stainless Steel Body with M.S. Base Frame

✅ Capacity: 225 Kg., 350 Kg., 500 Kg., 750Kg., 1000Kg., 1500Kg.(250 Gsm)

✅ Complete Stainless Steel Body.

✅ Heavy duty brake drum.

✅ Heavy duty differential Gear unit.

✅ A.C. Frequency Drive.

✅ Stainless Steel Cladded Main Roll

✅ Circulation System with 2.0 H.P.

🔶 Payment, Taxes and Delivery

Payment: Before dispatch of machinery, 40% advance and a balance against the proforma invoice.

Delivery: Delivery of machine ideally comes within 4 to 6 weeks.

Freight: Will be paid by the customer.

Sales Tax: GST 18% (Domestic Orders) Or Vat 4% +1% No CST against form “H”( export orders).

Installation: Will be charged extra per machine over and above the price.

1. Select Product

Choose the required specification & submit the details.

2. Get Offer

Get a Detailed Offer.

3. Pay The Advance

Pay the advance amount as per agreed terms.

4. Product Under Construction

Product goes under Construction according agreed time.

5. Pay The Rest Amount

Pay the balance amount as your machine get ready to dispatch.

6. Shipment Initiated

Shipment option available through Manufacturer.

7. Installation

Finally, the product will be installed at your plant.

Jigger | Fabric dyeing machine | 225 to 1500 Kgs. | Best buy

Jigger has been used for a long time to treat medium size lots of woven with open width exhaust dyeing process.Dye jiggers are available in many variants

Product SKU: D/J-1

Product Brand: Indian

Product Currency: ₹

Product Price: 5,25,000

Price Valid Until: 2023-08-01

Product In-Stock: PreOrder

4.5

| Fabric | Cotton, Cotton Polyester, Wool, Canvas, Silk |

|---|---|

| Machine Width | 1250mm, 1400mm, 1500mm, 1600mm, 1800mm, 2000mm, 2200mm, 2400mm, 2600mm, 2800mm, 3000mm, 3200mm, 3400mm |

| Type | OPEN, CLOSE |

| Capacity | 250KG, 350 KG, 500 KG, 750 KG, 1000 KG, 1500 KG |

Jigger | Fabric dyeing machine | 225 to 1500 Kgs. | Best buy

Jigger has been used for a long time to treat medium size lots of woven with open width exhaust dyeing process.Dye jiggers are available in many variants

Product SKU: D/J-1

Product Brand: Indian

Product Currency: ₹

Product Price: 5,25,000

Price Valid Until: 2023-08-01

Product In-Stock: PreOrder

4.5

Based on 0 reviews

Be the first to review “Jigger”

-

Dyeing Machinery

CP Dyeing

CP Dyeing

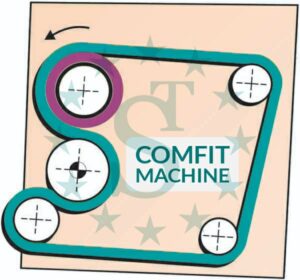

CP Dyeing is dyeing machinery to Dye Fabrics rapidly. Dye Fabric. This machine has the following features.

- First, it dyes the cloth with reactive colours. The CP Dyeing is installed with a small vat & shaped to allow fabrics an adequate contact time for absorbing dye bath through the high speed of cloth.

- In other words, CP Dyeing dyes the cloth rapidly, with less place required.

- Secondly, Reduced liquor volume is possible due to the fast exchange of fluid. Therefore, less wastage of resources.

- Thirdly, CP Dyeing‘s Roller width can be made from 1200mm to 3000mm depending on the client’s need.

🔶 Special Features:

✅ Versatile because it is equally suitable for Light and Heavy fabrics.

✅ Utilising of “Two Nip Two Dip” method ensures consistent colour penetration.

✅ The Top rubber roller is anti-deflecting construction.

✅ On Nips, pneumatic loading can be as much as 6 tons.

✅ Minimum loss of dye liquor because of low Dye liquor content in the trough.

✅ The main Batcher can batch cloth up to 1500mm Dia.

✅ Drive to both padder & Batcher by inverter-controlled AC Drive.

✅ Minimum tension between padder & Batcher is for perfect winding of cloth.

✅ The minimum distance between Padder & Batcher is to avoid oxidation.

✅ Machines are available from 1200mm to 3000mm roller width.

SKU: n/a -

Burner, Heating Solution

Burner 550 – Stage 3

Burner 550 | Heating solution

This heating solution burner 550 comes to volume, potential, and cost efficiency. The Burner 550 is a series stage 3 covers output ranges under 80mg/kWh. These gas burners were designed with an advanced combusting head which provides consistent combustion even under difficult working conditions.

The placement of the components inside the burner permits easy and precise regulation and maintenance.

Benefits

🔥 Amazingly efficient at burning gas

🔥 Stable flame no matter what kind of weather you’re dealing with

🔥 High efficiency (80mg/kWh)

🔥 Efficient, clean combustion

🔥 Power is increased without complications✅ Easy to maintain

✅ Great energy savings

SKU: n/a -

Accessories

A Frame

A-FRAME Trolley

A-Frame trolley is one of the most required Accessories in Textile Plant and Mills. A-frame’s objective is to carry the fabric and make it easy to manoeuvre inside the facility while different processes such as measuring, washing, cleaning, dyeing or printing, and finishing.

A-frame trolleys are also Utilised in rotating stations by simply adding an extension to them.

A-frame trolleys come in different sizes from 44 to 130 inches roller width depending on the customer. A-frame trolleys take less space than bucket/box-type trolleys. It gets easier to manage them and store them in one place.

Inshot A-Frame Tolleys are best to manage and store the grey to finished material in a clean and sorted way that helps to identify the fabric lot.

Many Textile mills and Export houses have been using it for a long time, making it reliable and one of the solutions to manage the fabric.

🔸 Technical Specification

✅ A FRAME’s top roll fabricate from M.S. Seamless Pipe (Ebonite quoting).

✅ The end shaft is RIB constructed or As per the buyer’s suggestion.

⭕ Cladding of S.S. Sheet on a batch roll. (Optional)

✅ The front side pooling system is a swivel-type M.S. fabricated bracket with 10″ x 2 wheels.

✅ The rare side is of fixed type 12″ x 3″ wheel.

✅ Batch coupling is fit on a batch roll for rotating.

✅ A-FRAME is manufactured from an M.S. channel (100/50mm) x 6mm wall thickness.

SKU: A/T-1 -

Dyeing Machinery

Regular Jet

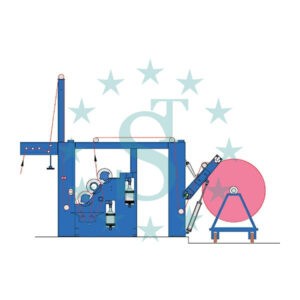

Regular Jet dyeing

This machine is best for polyester fabric dyeing cause it runs on a high pressure of high-temperature water. Regular Jet dyeing is economical because the low liquor ratio reduces everything.

The fabric inside this polyester dyeing machine moves solely due to the force of water.

It is user-friendly because, If we compare it with a Long tube dyeing machine. Four valves are necessary to control the fabric’s motion. Here in Regular Jet dyeing, there is only one valve.

Absent of reel, reduce connecting electric power, maintenance of two mechanical seals and breakdown time if Jet pressure and reel speed are not synchronized.

Nearly 4000 without fabric drive reel devices are saving energy and lowering pollution in 20 countries.

🔸 Technical Specification

✅ Capacity: 25 to 400Kg.(Single Tube)

✅Ultra Low Liquor Ratio – 1:1 (Wet Fabric)

✅ Dye – 30 To 450 Grms./Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

✅ High Temp. – Up to 140 ° C.

✅ Fabric Speed – 300 Mtr./Min.

✅ Vessel: SS 316 LBest Polyester dyeing machine with a low liquor ratio in a Jet dyeing form.

SKU: D/JD-1 -

Burner, Heating Solution

Burner 90 – Stage 2

Burner 90 | heating solution

This heating solution gas burner 90 is equipped with tangential ventilation, representing the smallest of Stage 2’s gas burners.

35 kW burners can be arrange to use external combustion air upon request. In this case, the burners will be supple with an airtight air intake that can be linked outside the location of the installation through a duct with an extension up to ten meters.

Its small size makes it a viable heating solution for small spaces like workshops, small scale industries and sheds.

Benefits

🔥 35kW burner can be arranged externally

🔥 5 different aluminium housing options are available

🔥 Highly efficient design

🔥 Compact design

🔥 Designed for use in smaller buildings

🔥 High efficiency (120mg/kWh)

[spbsm-follow-buttons]

SKU: n/a -

Accessories

Rubber Blanket

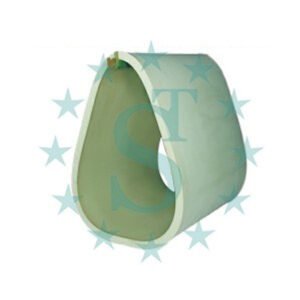

Rubber Blanket

in the textile finishing process for pre-shrinking fine, lightweight cloth, Twills, Drills, & other medium-weight fabrics. Rubber Blanket has the following features:

- Firstly, the Rubber Blanket is produced from the highest quality, dirt-free natural rubber and selective quality polymers to give extremely high compressive strength to the product.

- Secondly, it ensures a non-stick surface for excellent fabric finish during the shrinkage process of textile.

- Thirdly, the high-quality speciality rubber additive with high-performance anti-degradants is selected to prevent surface degradation of the Rubber Blanket at high-temperature processing, which gives excellent heat resistance and superior flex life to the product.

- Fourthly, a Superior quality Rubber blanket can effortlessly process at high steam pressure on modern high-speed machines to give shrinkage-free fabrics. Because of the heat resistance nature of the Rubber Blanket, it Gives uninterrupted service before stopping the machine from grinding the new smooth surface.

- Fifthly, The good abrasive surface and excellent flex quality of the Rubber Blanket are Expected to give at least 10 to 15% higher meterage of fabric under ideal processing conditions than other brands of Rubber Banket available in the Indian market.

Moreover, Producers of lightweight, low shrinkage potential, 100% cotton or cotton/polyester, commonly report from 15 million to 20 million meters of productive life.

🔶 Technical Specification

- Hardness: The recommended hardness of a Rubber Blanket is between 36 degrees to 39 degrees depending on the fabrics to be processed.

- Fabric Width: offer current width of 1200mm to 3500mm.

- Usually, Rubber Banket should be 150 mm to 200 mm wider than FELT the cloth to be processed.

- Pressure Circumference: The standard internal circumference of the Rubber Blanket is 3962mm (13 feet)

- Thickness: The most common thickness of a Rubber Blanket is 67 mm (2.5/8″) and varies up to 70mm. The higher thickness will initially require higher force for outer surface elongation as the Blanket turns around the pressure. Results in cracks on the outer surface & will need to grind the surface frequently and often rubbing the Rubber Blanket from the inner surface. Usually, Rubber Blanket thickness depends on the required shrinkage in fabrics.

- The Rubber Blanket has a maximum shrinkage capacity of Up to 15% for lightweight fabric processed on a comfit type machine 50 mm.

- Usually, Rubber Belt thickness depends on the shrinkage needed in fabrics. For lightweight processed fabrics with low shrinkage fabrics such as poplins, fancy prints & synthetics dress material etc., a Belt thickness of 55 mm is required. This rubber belt will have a shrinkage capacity of 5-8% for processing heavy weight fabrics like Denim, Twill, Drills etc. thickness Belt of 67-71 mm is needed. The Rubber Belt has a maximum shrinkage capacity of Up to 15% for lightweight fabrics processed on a comfit type machine 50 mm A thick belt is most suitable with 3-5% shrinkage.

In conclusion, Rubber Blanket is best suitable for the garment industry or dyeing & printing plants which use the machines like Compressive Shrinking Range or Zero Zero & Comfit.

SKU: n/a

There are no reviews yet.